Streamlining the Moldmaking Process

Adopting a production mindset can increase productivity and efficiency, and reduce the probability of errors that cause delays and scrap.

Mold shop owners must think about mold manufacturing in a new way, “productionizing” their processes to successfully meet customer demands, shorten lead times, reduce setup times, improve machine utilization rates, cut machine cycle times, decrease spotting times and address operator skill sets.

Adopting a production mindset entails transitioning a product or process from one-off fabrication to a series of common procedures that can increase productivity and efficiency, and reduce the probability of errors that cause delays and scrap. These common procedures can be realized throughout the mold manufacturing process, including using CAM toolpath templates to standardize many of the cutting parameters, standardizing tooling and assemblies, and adopting modular workholding.

One of the primary sources of inefficiency is setup procedures. From the initial squaring up of parts to roughing, heat treating, finishing and EDM, moldmakers often run through numerous setups that frequently entail change-over among multiple machine platforms. The result is substantial labor time that limits the shop’s ability to reduce lead times and increases the risk of errors due to the inability to locate the workpiece.

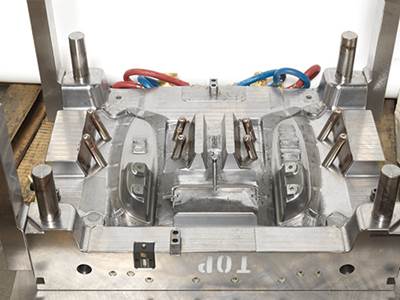

Setup issues become even more troubling as design complexity increases with multi-face machining requirements. If a moldmaker is operating traditional three-axis machining centers, an application calling for machined features on two or more sides of a workpiece could entail multiple sequential setups on multiple machines. Mold shops that try to improve workpiece accessibility through custom setups have their own unique challenges, including positioning inaccuracies and demand for a very experienced operator skill set. This is where new modular workholding solutions can have the greatest impact, such as an FCS clamping system.

This modular clamping system is designed to provide quick, custom setup options for unrestricted access to five workpiece surfaces, which can allow moldmakers to spend less time on setups and more time on machining. The system creates a three-dimensional grid in every machine installation that maintains positioning repeatability within 6 microns (0.0002 inch) on every setup. The base gage features a grid of threaded holes and precision counterbores spaced evenly apart by 50 mm to within 5 microns, permitting fast, precise modular setup adjustments that are safeguarded from human error.

Positioning accuracy is enhanced more by the system’s titanium-nitride-coated, hardened steel rings. These rings are installed between the workpiece and a cylindrical clamping body, held tightly in place by an H7-class precision counterbore in the workpiece or base gage, and precision-ground tapers on the other. The result is a secure fit with micron-level repeatability. Serrations in the clamping mechanism with matching serrations in the rod make this system rigid. As the clamping mechanism tightens on the rod, the clamping serrations pull on the rod’s matching serrations, delivering precise tension on the rod, the seat and the ring to secure the workpiece.

Users of this type of modular clamping may also want to take advantage of virtual-design software that allows users to design the clamping system based on the CAD model of a workpiece. The software projects the clamping system grid onto the workpiece to identify the most efficient workpiece positioning for machining and chip evacuation. After checking for possible interferences with other holes, it automatically arranges the clamping system’s drilled and tapped holes and H7-class counterbore based on the dimensions of the workpiece, and a combination of pallets and clamping available.

With the skilled labor shortage and growing demands to reduce scrap and unproductive time, a modular clamping system enables moldmakers to apply a production mindset and simplify manual labor activities, eliminate setup error, and operate more efficiently and profitably.

Related Content

Fundamentals of Designing the Optimal Cooling System

The right mold components can help improve mold cooling and thereby produce higher-quality parts.

Read More6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

Read MoreHow to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreMaintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

Read MoreRead Next

Adopting a Production Mindset

An HMC with a pallet changer and modular fixturing system has streamlined job change-overs at this Tier 2 automotive toolmaker.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More