Streamline Your Mold Cleaning Process

Ultrasonics can help your shop reduce labor costs and product waste while boosting efficiency and product quality.

Plastic injection molding offers many benefits to the buying public. Lightweight, durable plastics de-signed to enhance the American way of life. Injection molders benefit from a more diverse array of products they can sell and the profits generated by those sales. The challenges for the plastic injection molders are keeping up with demand, discovering advanced techniques to expand their manufacturing base and keeping their molds clean and in good working order.

Most injection molds are still cleaned the old fashioned way with labor-intensive hand scrubbing and solvents. Though nostalgia is great for many things, cleaning molds should not be one of them. Molds become contaminated with grease, hydraulic oil, rust, grime, carbon, aluminum shavings and material gassing. Gordon Schwartz, Program Manager of Kaysun Corporation in Manitowoc, WI, received a challenging project: find a better way to clean his company’s injection molds.

Shopping Around

Kaysun Corporation was established in 1947 during the early years of injection molding, bringing plastic goods into the American economy. Their first products were model airplane parts, cookware and commodity items. The business has been expanding rapidly for the past 12 years because of their willingness and desire to invest in cutting-edge technologies to solve a variety of customer needs from automotive to industrial to military markets.

Schwartz attended a lean manufacturing certification course. His central task was to streamline the mold cleaning process. After extensive research on the Internet and investigating other manufacturing companies in the area, Schwartz found his solution in ultrasonics.

At the time, Kaysun employed three technicians in the mold maintenance department. Because Kaysun’s business was expanding, they were going to bring on a fourth individual to handle the increased volume.

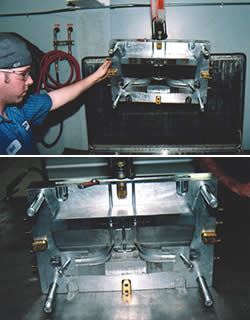

Schwartz brought three different manufacturers of ultrasonic equipment into their facility to evaluate their equipment and service. After some testing Schwartz determined that Kaysun could avoid hiring that fourth technician for the price of a $16,000.00 ultrasonic parts washer.

While all three ultrasonic machines tested out well, Kaysun chose a larger floor model based on its demo, its filtra-tion package, easy operator interface, exceptional price value and customer recommendations.

Integrating Ultrasonics

Wayne Hurkmans is the head of the mold maintenance department. His charter was to integrate the ultrasonic parts washer into Kaysun’s operation and find the right balance of chemistry, time and temperature.

Hurkmans chose to use a water-based, biodegradable mold release specifically designed for cleaning injection molds with burnt-on crystalline plastic residue. The soap was mixed at a 13:1 ratio with water. The bath temperature was heated to 150°F. Depending on the type of mold, the intricacy of the mold and the type and level of contamination, molds are cleaned in a hands-off ultrasonic environment between 5 and 60 minutes.

Kaysun’s maintenance department generally disassembles the mold before placing the parts into the washer. After cleaning, molds are rinsed in hot water to remove any soap or residue, then blown dry with compressed air and placed back on a machine or into stock for the next run.

Hurkmans confirmed that the time benefits have been outstanding. A mold with baked-on, carbonized hydraulic oil might take as long as three hours to clean by hand. With ultrasonics, it is only one hour. Even light to moderately contaminated molds might take 30 to 60 minutes with manual cleaning, while 10 minutes is all that is required with the ultrasonic washer.

But time is only one of the benefits ultrasonics has for plastic injection mold cleaning. Hurkmans continues, “Molds look brand new. Ultrasonics is quicker and cleans better, especially for intricate parts. Tool life is extended as well. Everything is just better with ultrasonics.”

Vents built into molds allow gas to escape during the gas-off process, but these vents become clogged with usage. Clogged vents trap gas—resulting in gas burns in the steel mold, thereby shortening the life of the mold. Ultrasonics cleans the vents more thoroughly, maximizing the stretch of time the mold can stay in the run before it must be rotated out.

Cost to Value Ratio of Ultrasonics

Kaysun has found an excellent cost to value ratio in using ultrasonics. Molds that are not properly cleaned generate waste product. As an example, out of 100 pieces, six may be out of spec and thereby rejected. Cleaner molds are easier to run and maintain. “The better the mold, the better the parts, and the longer the mold keeps parts within specification,” says Schwartz.

Molds that are extremely well cleaned with ultrasonics provide positive results throughout the production process:

- Less start-up time

- Less waste

- Less labor time with reduced troubleshooting required by the mold technician

- Less time that a line needs to be shut down

One final benefit of a properly cleaned mold is the ability for the injection molder to go after more profitable, highly-engineered projects. Because of deeper crevices and cracks, an injection molder confined to hand cleaning cannot effectively and profitably compete in this arena. They are confined to the lower profit, highly competitive projects with mainly flat surfaces.

Ultrasonics helps Kaysun Corporation stay on the cutting edge by reducing labor costs and product waste while boosting efficiency and product quality. It is a technology that adds to the company’s profitability, making it a wise investment.

Related Content

Products and Services for Multiple Moldmaking Needs

New year, new technology roundup! Featured here is a collection of product offerings, from profile milling cutters to industry-specific CAD/CAM software to innovative hot work tool steels.

Read MoreWhat You Need to Know About Hot Runner Systems and How to Optimize Their Performance

How to make the most out of the hot runner design, function and performance.

Read MorePrecision Welding Services Offer Rapid Turnaround Mold Repair and Reduced Molder Downtime

X-Cell Tool & Mold relies on outsourced, high-quality welding repairs from Lewis-Bawol Welding to ensure its customers' molds are back in production quickly and affordably.

Read MoreMoldMaking Technology's Most-Viewed Content 2022: Products

MMT shares the five top-viewed technologies, equipment and services of 2022 in each Engineer, Build, Maintain and Manage tenet based on Google Analytics.

Read MoreRead Next

Cleaning Molds: Part I

Cleaning a mold is a critical part of the repair process, but many myths must be dispelled.

Read MoreChoosing and Using the Right Mold Cleaners

Knowing the requirements of offline and online cleaners yields cleaner molds.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;maxWidth=300;quality=90)

_970x250 4.png;maxWidth=970;quality=90)