Statistical Process Control: Beyond the Data

Statistical process control used correctly allows moldmakers to connect data sources, collect data and issue failure alarms in real-time.

With appropriate data analysis tools moldmakers can move from simply controlling processes to optimizing processes. Too often data collection does not allow companies to drill down and get to the root cause of process variation. Only when they turn data into knowledge are process improvement efforts based on fact, not opinion. All fabricators and moldmakers are able to achieve a strong lean variation dynamic through the use of real-time statistical process control.

Beyond the Data

Collecting data is not a challenge for many in the moldmaking and fabricating enterprises; however these groups may think they are data driven, and in a way they are, but they have fallen far short of their entitlement. If you take the same data and make one very subtle change to how you use it, you can make a tremendous stride forward in becoming data driven.

In Figure 1, the starting point is the same: measure an output. But the subtle difference is that instead of comparing it to the specification (the requirement), it is compared to what is expected based on some simple statistical techniques. Now instead of rejecting a product based on the failure to meet requirements, companies using SPC solutions can focus on how to use the data acquired to improve the overall process. This is called listening to the voice of the process.

SPC: Closing the Loop

Once companies find the process has changed, they are able to investigate the reason for the change and improve the process. If the process hasn’t changed, then companies can evaluate whether they are satisfied with the process output and improve it by finding ways to reduce chronic variation. This is how moldmakers and fabricators can increase the value of data.

Four Aspects of Data Value

In a manufacturing environment, there are four aspects of the value from using data.

1. Product Release and Control

Use data to validate products are acceptable for shipment. This data is primarily accept/reject type data, and may be based on either measurements or some other kind of pass/fail criteria, and is based on the voice of the customer.

2. Process Control

Apply statistical process control tests to key products and processes. These activities use the Voice of the Process to determine the stability of the process. React immediately to instability and unexpected variation.

3. Continuous Process Improvement

Use data to close the loop on our processes and drive continuous improvement. People must be trained to use this data to look for hidden sources of variation and correlation between key input and key output variables.

4. Data Visibility and Transparency

Data must be readily visible at all levels of the organization. Every stakeholder, from process owners to the leadership team, must be able put their fingers on the performance data that matters to them.

Summary

Only the best SPC solutions ensure that information is summarized in easy-to-understand dashboards that help separate signal from noise, so they don’t react to the wrong things. Furthermore, they can readily get to the underlying data to better understand the drivers of their key metrics.

Related Content

How to Use Thermal Management to Improve Mold Cooling

A review of common mold cooling issues and possible solutions, including 3D printing applications.

Read MoreHow to Use Diffusion Bonding to Optimize a Mold’s Thermal Performance

Joining dissimilar metals has tremendous potential for conformal cooling, but to successfully use diffusion bonding, a mold builder must understand the complexities of the interface and its effect on the chemical and thermo-mechanical properties of the bond.

Read MoreThe In's and Out's of Ballbar Calibration

This machine tool diagnostic device allows the detection of errors noticeable only while machine tools are in motion.

Read MoreWhat is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read MoreRead Next

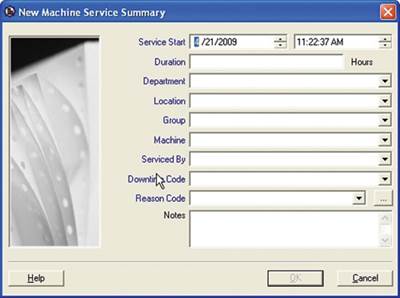

Data Collection Software Streamlines Machine Maintenance

Available from Shop Floor Automations, Manufacturing data collection (MDC) is a data collection tool that tracks and reports machine activity to help streamline jobs on the shop floor. Specifically designed and built for CNC machines, it can also track machine status to help the maintenance department identify machines that are down for repair, preventative maintenance or other reasons.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

.jpg;maxWidth=300;quality=90)