Sophisticated Hot Runner System Offers Longer Mold Life for Medical Molds

Multi-tip nozzle saves the day for high-production, high-cavitation medical molds—slashing cycle times, generating no waste, and needing minimal maintenance.

For 40 years, Cavaform International, LLC (St. Petersburg, FL) has been manufacturing precision injection molds and mold components for a number of industries. However, the company has earned a stellar reputation in the medical market, specializing in catheter tipping dies and high cavity, high tolerance tooling for the medical disposables industry. The ability to provide these types of molds in the medical industry is an emerging trend in the medical market.

Cavaform International has shipped in excess of 1 million cavities and components to companies worldwide. According to the company’s General Manager, Sales/Engineering Chuck Massie, 75 percent of its business is injection molds, the balance being injection mold components. “The biggest portion of our business is medical disposables,” Chuck says. “The other three primary areas are writing instruments (pens, pencils and markers), cosmetic packaging (lipstick tubes and mascara stems) and conventional packaging (caps, closures, sticks and tubes).

Featured Content

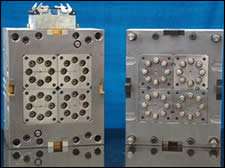

“Most of the medical molds we build are for high volume disposables—needle shields, syringes, test tubes and vials,” Chuck continues. “Typically, they are high cavitation molds (32, 64 and up to 196 cavities). Some of the molds are capable of making a couple million parts per day. They tend to be multiple molds; they have a long life and the product doesn’t tend to change year after year. They are made in very, very high numbers and because of that, the molds have to be guaranteed to have interchangeable mold components—very robust, mostly hot runner to avoid waste or regrind. With a lot of the medical components you can’t use regrind, so that’s another reason to use hot runner systems. That’s where we have staked our reputation—for building these high cavitation molds.”

Medical molders and OEMs typically don’t carry a large inventory, so a moldmaker needs to provide a mold that will perform consistently to avoid downtime. Cavaform needed to find a hot runner system that would turn these complex molds around quickly. When looking for a hot runner system, the company needed one that would provide control at the gate and simultaneous gate opening in a wide processing window, with low injection pressure and low risk of core deflection. At the same time, Cavaform was looking for a multi-tip nozzle to run multiple parts off of one nozzle. And, the system had to accommodate medical parts that typically have thin walls and are cylindrical.

Market Challenges

Obviously, finding the proper hot runner system to suit the company’s criteria was a formidable challenge, but one General Manager, Manufacturing/Molding Dave Massie was ready to tackle. “The com-ponents themselves have to be very accurate, close tolerance; typically we are working below a half of a thousandth,” Dave explains. “This tolerance is not unusual. We have a customer that has us hold a .0001, +/-.00005 in some areas of the molded product. You have to have very accurate machinery, highly skilled people, and high quality standards to measure and maintain those types of molds.

“One of the difficult challenges is to find a hot runner solution that the customer will endorse,” Dave notes. “Typically they want no sub-runners that create waste, so the challenge is to find a direct-gated application that you can design a robust tool around. Today, quality is a given, though demanding, we must provide a tool with long life and minimal maintenance.”

Cavaform International turned to Mold-Masters Limited (Georgetown, ON)—a manufacturer of hot runner systems and components—to offer them a complete solution in the form of its Melt-Disk™. “There aren’t endless choices in the market,” Chuck notes, “and some hot runner companies are just better at offering the whole package than others. When we looked at systems, one, we were looking for long life. Again, these medical molds are designed to run with minimal maintenance for multiple millions of cycles and a long warranty is important.”

Also important is the ability to use a multi-tip nozzle, something not many hot runner suppliers offer. “With high cavitation molds you can do multiple parts off of one hot runner nozzle (two, four, six or eight parts)—so instead of having to have 64 nozzles for instance, you might only have to have eight,” Chuck says. “That cuts costs on both hot runner systems and also cuts cost on the controllers. You don’t have to have as many control zones to run the large cavitation molds. So it economizes an element of cost for the OEM doing the actual molding.”

Exemplary service also was sought after by Cavaform International. “If there is a problem or downtime, a lot of the OEMs expect someone to be there within 24 or 48 hours to perform service,” Chuck states. “That is something that we as a moldmaker like to have ourselves, so we want support from our hot runner supplier rather than have to send someone from our staff. Dave adds, “It’s a mandatory requirement today that the molds that we build need to have a service tech at our customers’ disposal within 48 hours. Anything less than that would probably be unacceptable by most of our customers’ standards and I couldn’t tell you how many people in the industry would fall out of that capability.

With a majority of medical OEMS doing Just-In-Time manufacturing, they don’t often have a large inventory, Chuck says. “They are molding and transporting parts across their manufacturing floor and putting together a medical device or a syringe so the parts are actually assembled in a matter of hours,” he affirms. “So, if a mold goes down and they don’t have backup readily available, it obviously affects their sales and productivity.” If it is a specific hot runner problem, Mold-Masters will service the mold.

System Specifics

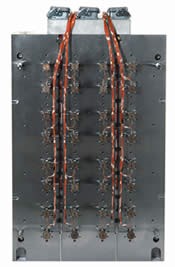

Mold-Masters Marketing Manager Mike Ellis explains that Melt-Disk’s design provides foolproof technology for side hot tip gating of small parts, regardless of the thermoplastic material. “Melt-Disk is a precise melt delivery system integrated into your cavity plate/cavity insert assembly,” Ellis states. “Its design does not compromise cavity strength or cooling requirements, nor does it interfere with cavity side components such as pins or unscrewing mechanisms. The key to its performance is the precise balance achieved by a dedicated heating element that ensures optimal heat control in the gate area. It’s perfect for thin-walled, cylindrical deep draw parts such as pipettes, syringe barrels, needle shields or smaller parts where only side gating is permitted. Simultaneous side gating is available for two, four, six or eight parts per drop, with tips angled at 15°, 30°, 45° and 60° from horizontal.

“In these high cavity, high output production environments it’s critical that the processor achieve the following: superb gate control, simultaneous gate opening, wide processing window, low injection pressure and low risk of core deflection,” Ellis adds.

The Melt-Disk’s three-fold design addresses these criteria: the geometry of the Melt-Disk ensures complete mechanical and rheological balance inherent in its design; complete heat control at the gate area is independent of the hot runner system; and conductive precision-finished tips and the insulative gate seal provides optimal thermal conditions at all cavities. “Especially when dealing with medical components, application specifications are very demanding,” Ellis notes. “The inherent flexibility in the design and thermal control makes the Melt-Disk perfectly suited for this industry.”

In the part concept stage, consideration should be given to the preferred gate location, according to Ellis. “It should be chosen by taking into account the part filling characteristics desired,” he emphasizes. “Typically, the preferred gate location is in the thicker section of the part. It is advisable to locate the gate near a step on the part surface due to the shearing action of the gate that occurs during part removal.

“The melt link is where the thermal expansion of the Melt-Disk and Master-Series nozzle seals the assembled system,” Ellis continues. “After the assembly of the cavity plate, with the Melt-Disk integrated into the Master-Series hot half, the radial expansion of the Melt-Disk and the transfer link materials create a seal at processing temperature. Also, the thermal expansion of the nozzle in the axial direction into the Melt-Disk seat seals the front face of the melt link. This seal ensures ease of integration and eliminates the risk of downtime during the operation and maintenance of your mold.”

Application in Action

Cavaform recently built a mold for an aspiration needle that is used to go into a drip bag or rubber grommet for delivering medicine for a patient. “It’s a 32-cavity mold that runs in a 75-ton electric press and it has a very small footprint,” Dave elaborates. “The customer gave us the tool and asked us to retrofit it for the new product. When we tried, the hot runner system the customer had in place failed to perform. It was not able to deliver the melt to the gate to fill the tool. The existing system had been designed for polypropylene did not have the flexibility to deliver the acrylic material that the new product required. The previous hot runner system had insufficient abilities to keep heat in the gate area to keep the gates open. After we had proven that out to the customer’s satisfaction, they gave us the green light to redesign the part from scratch and build the mold from scratch—with the Melt-Disk system. This system was the most viable solution to this customer’s problem.”

The mold has a four-drop Melt-Disk, so there are eight parts molded from each hot runner nozzle. It runs an eight-second cycle and is fully automatic. “This particular material is acrylic, a slightly higher cost material—so there is no waste—the only thing that falls out of the mold is the finished part,” Dave says. “The system’s nozzles can be accessed in the press and cleaned, should there be a blockage because of something in the material, and the mold put back in service in a matter of 15 or 20 minutes. Again, downtime when you are under molding conditions should be minimal.

“Another advantage to using Melt-Disk is that with all of the materials we have used it on so far (polyethylene, polypropylene, acrylics, polycarbonate and nylon), we’d found that because of the way the nozzle’s heating element is designed, we are able to run a lower temperature profile—by an average of about 10 percent,” Dave continues. “For instance, in polypropylene, you can drop the temperature approximately 50 to 60 degrees from conventional nozzles. This accomplishes two things: puts less stress on the part so you are able to mold straighter with less warpage—particularly a long part like a pipette; and the second advantage is since you have less heat being put in, the part cools faster, which usually equates to a faster cycle time. So, you get a lower stressed part and a faster cycle—which equates to profitability to the molder.”

Dave also points out that since a multi-tip nozzle allows multiple parts to be molded off of a single nozzle, fewer control zones are needed on the controller—thus saving money on peripherals by not running as many control zones. “You only need two control zones, one on the disk and one on the main body,” he comments. “Whereas if you were using a conventional one part per nozzle you would have to have eight control zones and would need a much larger, more costly controller—and a bigger mold. Then you would have to run it in a much larger press, which can lead to a problem with physical spacing.”

As for installing the system, Chuck notes it is a little unconventional but with a little practice, not a problem. “The Melt Disk gate inserts must be placed laterally on the probe tip seals and the retainer block (either round or square) is vertically installed over the gate inserts,” he comments. “Usually these are face mounted or parting line mounted and can be removed in the molding injection press for service or replacement of gate inserts, probe tips or nozzle seals when required.”

This particular mold’s success story has resulted in Cavaform International using the Melt-Disk system almost exclusively for side-gating methods. “When you get into engineered resins like acrylic, polycarbonate and nylons, you have to have more sophisticated technology to deliver the heat to the gate and that is where Mold-Masters is probably better than anybody.”

“In closing, numerous medical, high volume molded products can be direct side gated or angle gated using the Melt Disk system,” Chuck states. “Medical products such as pipettes, syringe bodies, needle hubs, thermometer probe covers, IV connectors, and many others are prime candidates for this new hot runner technology.”

RELATED CONTENT

-

7 Key Advantages of Hot Runner Systems

While both hot runner and cold runner systems have their benefits, for design flexibility as well as reduced cycle times and costs, hot runner systems will probably be the better choice.

-

Hot Runners and Valve Gate Systems: A Moldmaking Team

Valve gates provide several advantages when using hot runners, including better appearance, safety and an overall better product. There are several types of valve gates, and it is important to choose the right one for your project.

-

Four Key Uses of Prototyping

Prototyping helps evaluate and test a design, clarify production costs, sell a product and secure patents.