SME Bright Minds Mentoring Program

Rapid prototyping (RP) experts introduce novices to the fundamentals of RP technologies through an innovative tradeshow experience.

Last May, the SME continued to foster the development of RP by introducing the Bright Minds mentoring program—an innovative program that paired students with an industry expert mentor at the RP&M 2004 Conference & Exposition. The students gained an opportunity to learn about RP, tooling and manufacturing by attending the exhibits and conference sessions and interacting with their mentors.

According to Bright Minds chairperson Michael Siemer, president of Mydea Technologies Corp. (Orlando, FL)—an RP product development services provider—the overall goal of the program is to create interest, excitement and an appreciation for product development methods, tech-nologies and applications among high school students.

The Bright Minds concept originated with David Kasik, technical fellow of Boeing, who had led a similar program at the SIGGRAPH 2003 and 2004 expositions, notes Terry Wohlers, pre-sident of Fort Collins, CO-based Woh-lers Associates and Bright Minds program team member. "The Computer Graphics Pioneers—a loosely organized group formed in 1982 to provide historic continuity and a medium for exchanging recollections of the development and application of computer graphics—sponsored the program for area stu-dents," he explains. "Since I am a mem-ber of that group, I took the idea to SME in August 2003, and proposed we do a similar program."

The Specifics

According to Wohlers, the high school age students were selected via an application process from two schools in the Detroit area, and signed a code of conduct to ensure they acted in a professional manner while at the show. "Exhibitors were contacted prior to the show and encouraged to be supportive of the students—as they could be future buyers of RP technologies," Wohlers states. Additionally, the exhibitors were asked to provide samples of their processes so that the students could show them to others at their schools.

To choose the mentors, the Bright Minds program members invited those who served on the conference advisory committee to join them. "We chose others who we believed would do a good job," Siemer states. "Most were neutral in the sense that they did not work for a company that sold RP products, but we don't see any reason why they could not beÊmentors in the future."

Twenty students were chosen and then paired with industry professionals who guided them through the conference and exhibit hall. After an orientation at the beginning of the show, the students also were allowed time to themselves—traveling in pairs to portions of the trade show and conferences. They were provided a package that included information they could take back to school and share with fellow students and teachers.

In addition to providing a basic yet high-level overview of advanced design and manufacturing technologies, materials, processes and applications, students also learned how and why certain technologies are used and experienced firsthand applications. They were able to ask questions to the exhibitors and interact with industry professionals. "My two students told me that they were surprised by the first-class treatment that they received," Wohlers notes. "Not only did the exhibitors spend time explaining their products and how they are being applied, they gave the students sample parts to keep. The students were ecstatic."

Mentor Todd Grimm of T.A. Grimm & Associates, Inc. (Edgewood, KY)—an RP consultant—found his students "eager to learn and full of questions." Acting as their tour guide, he started them out by walking the show floor. "I introduced the students to the technologies by explaining how things worked and I introduced them to the vendors. We did this for all of the exhibitors. We then discussed what they saw, and I listed some conference sessions that would be good for them. With this, I sent them out on their own to explore RP. We regrouped, discussed the technologies, answered questions and went back to the show floor to dig in a little deeper.

"It was fun to see them mentally connecting the dots on how the technologies worked and what they could do," Grimm continues. "As they did so, they asked many questions that built off of the answers to the first question. It was a rewarding experience for me, and I know that the students got a lot out of the day." Tim Gornet, CAE consultant at the University of Louisville (Louisville, KY), also mentored two students. He sat down with them at the start of the show to go over the tradeshow floor layout. "I highlighted specific booths that they should go to that had equipment or processes of note. I also guided them in making sure that they asked questions and made sure they understood that there are no bad questions," he notes. "We then went to the show floor together for a while so I could see how they handled themselves in what I am sure was an intimidating environment for them. As expected, they started out a little shy, but as they spoke with the first few vendors, they became more relaxed. I think this was due to the excitement and enthusiasm of seeing all of the equipment and parts.

"I had to then moderate and present at the conference so I set them loose on their own," Gornet continues. "We met back up at lunchtime for a wrap-up and discussion of what they saw. It was great to hear them talk about their visits, which booths most interested them, and what technologies, processes, and softwares they wished they had. For some of them, I think it solidified their interest in the product design and engineering field as a career choice."

It worked for Keith Roberson III, one of the Bright Minds mentorees, who currently attends Florida A&M University and plans to major in mechanical engineering. "I basically wanted to learn more about the machinery used in RP and the type of education that would be needed to pursue a career such as this," Roberson notes. "I asked my mentor, Michael Siemer, a lot of questions and he provided me with a wealth of information. I am also in the process of contacting him to see if I can intern with his company in the future.

"My experience with the Bright Minds program was wonderful," Roberson con-tinues. "I learned a lot of information regarding the history of this industry and the future plans of the industry. The Bright Minds program has provided me with an experience that I shall never forget."

Overall, Siemer and Wohlers label the program a resounding success. "From what I could tell, most of the students dressed and behaved very well," Wohlers says. "I did not hear any negatives. We were thrilled at the feedback we received. Several people came to me saying that the program was a great idea. We'd like to do it again next year. With the RP industry maturing, those close to it are beginning to understand that we need to interest our youth in engineering and manufacturing in general, and RP and related technologies in particular, if there's any hope of the RP industry reaching its true potential."

Related Content

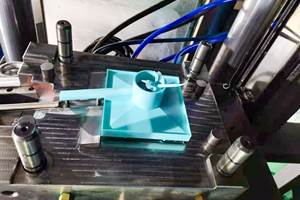

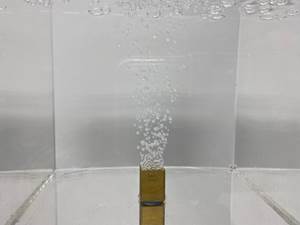

VIDEO: How can 3D Printed Tooling Improve Injection Mold Venting?

Proper venting is one of a mold builders toughest challenges as molders struggle to keep vents free flowing in production. Learn how to apply 3D printing to mold venting and the benefits of additive venting inserts.

Read MoreA 3D Printing Retrospective

A personal review of the evolution of 3D printing in moldmaking throughout the past 25 years.

Read MoreEvaluating Metal Powders for Conformally Cooled Mold Inserts

Mechanical properties and design software techniques reveal the benefits of a modified high thermal conductivity metal powder for 3D printing in moldmaking.

Read MoreVariable Density-Coated Tool Steel for High-Wear Molds

A mold builder can have an abundance of venting and fully dense solid areas in steel by using variable density sintering to eliminate gas trap defects in high-wear molds.

Read MoreRead Next

Rapid Prototypes + Moldmaking = Profits

Is there an easy way to avoid the pains of making mistakes in the mold building world? Absolutely! There are three simple steps that you can implement into your moldmaking process that will increase the moldmaking power of your shop and reduce your stress.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

_300x250 1.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)