Short Leadtimes, Customer R&D Boost Business for Dauntless

Fast time-to-market and product development work with OEMs hone California moldmaker’s competitive edge.

Looking back on 25 years in moldmaking, George Payton might conclude that he was always in training for the job that became his calling: owner and president of his own business, Dauntless Molds Inc. (Covina, CA), a specialist in the medical market.

Payton has worked at some of the leading moldmaking companies on the West Coast, in virtually every position—as an apprentice and machinery operator, and in design, sales and management. The only title lacking on his résumé was president.

The Journey

That changed in December 2004, when Payton and his wife, Cindy, purchased Dauntless Molds from the two owners who founded it 30 years ago. Both wanted to retire and Payton was looking to start his own shop.

“I had been wanting to go into business for myself for several years,” he says. “Moldmaking is my trade. I wanted a company that was a good place for workers, that does good work and provides great service.”

Startups in the mold building industry are difficult. When he heard Dauntless was for sale, Payton saw an opportunity to acquire a viable business. He and his wife contacted the owners. Both parties liked what they saw.

“Dauntless has a good reputation and the owners wanted to entrust the legacy of their company to someone who knows moldmaking.”

It was a done deal, and Payton, now 42, became an owner-entrepreneur.

His tenure has been successful. Business at Dauntless has grown 50 to 70 percent in three years, Payton estimates, and is on track to increase at least 25 percent this year over 2007. He declines to reveal sales figures.

The Dauntless Niche

Payton cites several reasons for the company’s success. The medical industry is strong in North America and elsewhere, and largely immune to offshore competition due to concerns about leadtimes and intellectual property issues. Product development remains strong as OEMs finetune parts or develop new ones to meet the needs of an aging population. There is also demand for building replacement molds, as tools fabricated in the 1990s wear out and become impractical to repair.

Dauntless specializes in Class 101 molds for diagnostic products, surgical instruments and optical components. Mold sizes vary, ranging from tiny optical tools that fit in the palm of a hand to large molds with 32 cavities. The company’s engineering capabilities are broad, and include multi-shot molding, micro molds and in-mold labeling.

Payton set out to increase business at Dauntless by investing in its capabilities. An important part of his strategy is automation. “We’ve purchased quite a few machines that run unattended as much as possible.”

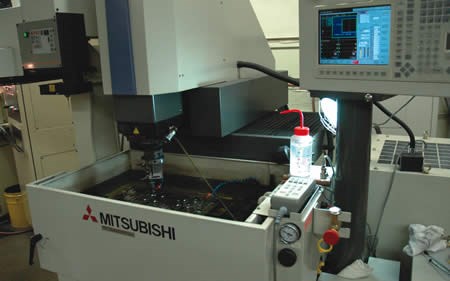

These include three Mitsubishi EDM centers: an EA8 wire unit with a robot that changes parts; an SX10 wire machine with a large workholding area that can run for extended periods; and a sinker with an automatic toolchanger, electrode changer, multiple work stations and lights-out operating capability. Dauntless has also bought two injection molding machines, one with a robot, to test the molds it makes and run prototypes.

Benefits of automation are, of course, improved quality and productivity, and manufacturing economy. But there’s another advantage: shorter leadtimes, a key requirement. “We’ve gained a 25 to 30 percent rate of efficiency in our work” since adding the equipment, he says. A mold that required 12 weeks to build three years ago can now be produced in eight weeks, a huge benefit for OEMs looking to bring products to market as soon as possible, and a major competitive edge for Dauntless.

R&D

The ability of Dauntless to deliver and certify molds so fast makes offshore competition irrelevant for all but commodity parts.

Leadtimes, though, are only one aspect of time-to-market considerations. Another major area is R&D. “We are helping some of our customers develop products,” Payton says. “They need a lot of development work turned around quickly.”

OEMs know what they want when it comes to part design, and have engineers who generate models. Payton explains, however, that Dauntless is increasingly asked to help assure that designs mold efficiently and economically—even to the point of working with a customer on resin selection. “They don’t always understand the correlation of part design to tooling.”

Dauntless routinely works with mold tolerances of .0002 inches or less. Payton recently assembled a team that does nothing but R&D work with customers on part development. This not only speeds final part design, but it’s a dealmaker when it comes to getting an order for production tooling.

Payton recently added an Operations Manager, Gottfried Haug, whose primary job is to prospect for business with companies Dauntless hasn’t worked with. Haug, who has medical market experience, is concentrating on OEMs that need the Class 101 tooling Dauntless builds. It takes several months to identify clients and meet with them. “One of the first questions they ask is, do we stand behind the quality of our molds for 1 million shots,” Haug says. “This is a must, given the high quality of components required for applications.”

The response to Dauntless has been “excellent,” and he expects to announce substantial new orders in the first quarter.

New Growth

One new area of business may be production molding. Haug is working on securing orders, and Payton affirms that one goal of the company is commercial molding. “We want to be a one-stop shop for our customers, where we design, build, run and maintain tools.” Projected molding volumes range from hundreds of thousands of parts to over a million.

Another potential market for Dauntless is respiratory care. Haug believes demand is growing for molded parts in this area, and includes it in his prospecting.

Dauntless Molds employs 32, of whom 24 work in the shop. The company has a relatively small facility—15,000 square feet. Payton says plans call for an expansion, possibly this year, though nothing is finalized.

California is a tough state for moldmakers to do business. Payton acknowledges the high cost of everything—land, taxes, benefits, insurance and salaries. Nevertheless, he believes Dauntless will continue to be successful, if it builds on its core strengths of competence and customer commitment.

“High-quality tooling and good service will keep the industry active in California,” he says, “and in the rest of the country.”

Related Content

MMT Chats: Marketing’s Impact on Mold Manufacturing

Kelly Kasner, Director of Sales and Marketing for Michiana Global Mold (MGM) talks about the benefits her marketing and advertising, MGM’s China partnership and the next-generation skills gap. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreConsiderations for Mold Base Material Selection

Choosing the right material can greatly affect the profitability and cost of your application.

Read MoreThe Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

Read MoreICYMI: MMT Chats: True Leadership Leads to Mentoring, Part 1

This trio from TK Mold and Engineering in Romeo, Michigan, joins me to discuss the role of leadership and culture in mentorship. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreRead Next

Dynamic Tool & Design, Inc.: Automatically Inclined

By fully integrating automation into its process, this shop services its customers from part design to sampling—and everything in between.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

_300x250 1.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)