Proper Use of Lifting Points

A look at unsafe lifting shortcuts that can lead to injuries in your shop and some possible solutions.

The proper use of lifting points is often overlooked in the moldmaking industry, leading to the continued use of inappropriate lifting points—increasing the possibility of failures and/or injuries.

While not as prevalent as in the past, forged eyebolt use is still a common and potentially dangerous practice if not performed correctly. Any nonvertical torqued lift on an eyebolt seriously diminishes the working load limit.

For example, an eyebolt rated for 2,000 pounds in a vertical plane only has a rating of 400 pounds (20 percent) at a 45-degree angle and only 300 pounds (15 percent) at a 90-degree angle. This also assumes the eye of the bolt remains fixed and shouldered to the load, which often is not the case.

Lifting Point Solutions

The proper solution is the use of lifting points that allow for swiveling of the eye and maintaining full engagement of the bolt in the tool. These lifting points adjust to the direction of the load—allowing for a safe lift. They also use the body of the lifting point as well as the threaded bolt or stud to support the weight of the load.

There are numerous products on the market designed for safe lifting at angles from 0 to 90 degrees, and the swivel hoist ring is best known. It is available in a variety of sizes, styles and prices.

A hoist ring requires its threaded fastener to be torqued to a specified rating to maintain its rated capacity. Its body swivels while the bolt remains stationary. Also its eye can pivot, usually up to 90 degrees. This is important for certain types of lifts.

A more recent style of lifting point is the true swiveling eyebolt, which allows the bolt to be threaded into the tool while independently allowing its eye to swivel a full 360 degrees. This type of lifting point is available in a variety of sizes and is economically priced between a forged eyebolt and a swiveling hoist ring. A swivel eyebolt does not pivot, but for many applications this is not an issue.

When a mold or die must be flipped, the center pull swiveling hoist ring and related lifting points are the correct tools. When a heavy tool is flipped, two lifting points are used on one side of the tool. As the load reaches its balance point and starts to fall onto its side, the lifting points need to both swivel and pivot at the same time, and the entire rigging unit (chains, wire rope, nylon sling, hooks and related hardware) must be properly designed and applied by the crane operator. Any binding of the lifting point could be catastrophic at this moment.

Properly torqued safety hoist rings work well here. The typical hoist ring uses a body, bushing and graphite-based lubricant to allow it to swivel, and an integrated oval or round eye to allow for pivoting. Another lifting point design uses ball bearings in the body to allow for swiveling and an integrated eye to allow for pivoting. The smoothness of the ball bearings makes this product perfect for this application. The ball bearing design does not require the lifting point to be torqued to a specified value. It only needs to be tightened by a wrench flush to the surface of the tool being lifted.

The side pull style hoist ring also is well suited to 90-degree lifts and for the flipping of molds and dies (due to its swiveling and pivoting capabilities). This design offsets the mounting bolt 90 degrees from the lifting eye making for convenient side mounting to the tool.

Clearly a well designed rigging system for safe lifting and moving of molds and dies requires the utmost care in design and application, and the use of the correct threaded lifting point is the final piece of this system.

Related Content

Mold Maintenance Continues to Matter: Enhanced Training Program in a New Facility

I attended a MoldTrax mold maintenance workshop in 2019 and shared my experiences, and despite changes in ownership, the workshop's remarkable value endures, as discussed in a recent Q&A with the current leadership.

Read MoreVIDEO: Insights and Best Practices for Mold Care

Slide Products President Michael Muth shares the products and practices he believes have helped the moldmaking industry the most when it comes to caring for molds.

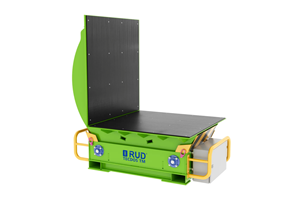

Read MoreIndustrial Drive Technologies Support Moving, Rotating Molds of All Sizes

RUD Tecdos solutions within its Mold Handling Solutions portfolio manage horizontal, vertical and rotational drive solutions for all environments.

Read MoreMachine Tool Breakage Detector Enhances Mold Manufacturing Reliability

Heidenhain’s new TD 110 is a fast, contact-free, in-process gage that can quickly inspect drill bits and end mills, even while spinning at their operational speed.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)