ProMoldGauer, Inc.: Acquisitions Key to Sustainability

Two key acquisitions allow this moldmaker to diversify its customer base and remain successful through difficult industry times.

In June 1999, when ProMoldGauer, Inc. was known as ProMold, Inc., the Tallmadge, OH-based moldmaker was enjoying success as a “zero-defect manufacturer of plastic injection molds” with a broad base of mold offerings and EDM services. Today, the company still thrives by continuing to diversify its customer base with the recent acquisition of a company whose specialty was vastly different from its own.

Growing Stronger

According to ProMoldGauer President Stefan Schler, it was back in 1998 when the company moved into a newly acquired larger facility “that marked the beginning of our modernization and the start of unattended machining,” Schler recalls. “We added a high-speed graphite mill, another CNC RAM EDM, another wire EDM, a high-speed, high-accuracy hard milling machine and a hole shooter (another EDM process for making very small holes).”

Fortunately, this investment in machinery helped the company survive the economic downturn that occurred after 9/11. “Our equipment allowed us to be competitive and accelerate our deliveries,” Schler says. “It kept us in the game. But then again, we had the overhead to pay for. So even though we weren’t getting as much volume in work, we were able to produce it more efficiently—hence we survived. We didn’t make a lot of money, but we survived.”

Not only did the company survive, it was poised to make an acquisition in 2006, after several attempts at other acquisitions fell through for various reasons. “It was a classic case of the tail wagging the dog,” Schler points out. “We were 10 people and Gauer was 45 people. We completed the negotiations and basically acquired Gauer on June 22, 2007.”

With this acquisition, ProMoldGauer was able to expand its offerings. “At that time, we had a very good reputation for building precision plastic injection molds with tight tolerance, but our limits as far as the size mold we could build kept us down to a 300- or 350-ton press. Gauer was very well known in the industry for making very large molds in the structural foam area, which is not as precision as the work we do. A different set of disciplines is needed to work in that field. So it was a good fit; there was a lot of synergy we picked up when we did this. We had a lot of customers that we weren’t servicing with large molds that could now come to us, and they had customers with small molds that they weren’t able to service.”

Optimism Abounds

Schler believes the United States is poised for a long-term revival in manufacturing, and plans to take advantage of it as time passes. “Although there will be up and down cycles during this time, the long-term trend will be up,” he predicts. “We have learned valuable lessons during each downturn, which we have applied to the business. I have some of the greatest people working for me in this industry and they’ve been with me a long time. The people we acquired also are wonderful. Our people sense our level of commitment. We empower them to make decisions and let them have responsibilities and the authority to make decisions.”

ProMoldGauer’s main goal is to continue to strengthen its position in the market, and then look for another “tail wagging the dog” acquisition in three to five years. Schler concludes, “If we don't take care of our customers, somebody else will!”

Related Content

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreMolds, Hot Runner Systems, Digital Technologies Highlight Sustainable Production

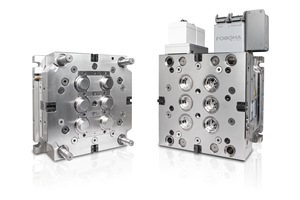

The Molding Solutions network at K Show displays Männer, Foboha, Synventive, Thermoplay, Priamus, Gammaflux and other external partners and their new or proven technologies for molding and moldmaking.

Read MoreEmbracing ESG: One Mold Builder's Path to Sustainability and Success

The story of how a company in the moldmaking, injection molding and metal parts industry is navigating the challenges and opportunities associated with sustainability.

Read MoreHow Hybrid Tooling Accelerates Product Development, Sustainability for PepsiCo

The consumer products giant used to wait weeks and spend thousands on each iteration of a prototype blow mold. Now, new blow molds are available in days and cost just a few hundred dollars.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More_970x90 3.png;maxWidth=970;quality=90)