Part Two of a Two-Part Series High Power Laser Technologies And Moldmaking

Using high power laser cladding for rapid tooling and tool repair.

Laser beam buildup welding or laser cladding has established itself as a precision coating method for surface protection and for reparation of highly stressed and complex formed tools on an industrial scale. The combination of the laser technique with other welding and heating methods (induction) contributes advantageously to the widening of the application field, offers totally new solutions for layer techniques and improves the efficiency especially of extensive or voluminous material buildups and coatings. This article describes the usage of high power laser cladding for rapid tooling and tool repair.

Process Principle

A laser beam is used to generate a melt pool on the surface of a workpiece. In a one-step process, metal powder (or a mixture of metal matrix and hard materials) is fed into the melt pool. By moving the laser/nozzle relative to the surface, the molten powder solidifies rapidly and generates a track, which is metallurgical bonded to the substrate.1

Advantages of Laser Claddin

- Low porosity

- Low heat input

- Metallurgical bonding to substrate

- Low dilution (less than 2 percent)

- Fine microstructures

- Precise deposition area

Modular Cladding Unit

The new cladding unit in Figure 1 has been proven in different applications for claddings with powders and powder mixtures. The main component is the coaxial powder nozzle; several versions can be seen in Figure 2. For the homogeneous distribution of the powder coaxial to the laser beam, two powder components are blown into a turbulence chamber. There a powder-gas-cloud is formed. This powder-gas mixture then passes through special shaped channels, which will calm it down and transfer it into a quasi laminar stream.2 After calming down the powder whirl and forming a quasi laminar stream, the powder-gas-mixture passes specially shaped channels. Simultaneously the streaming direction becomes parallel to the axis of the laser beam. Finally, a ring-shaped slit focuses the powder-gas-stream onto the point of laser incident.

The minimum diameter of the powder focus is about 1 mm. It guarantees a powder efficiency of 60 percent if the width of a single track is not less than 1.5 mm. For wider tracks higher values of the powder efficiency are possible. Using metal powders (specific weight ~ 8 g/cm3, grain size 25-90 µm), the typical feedrates are between 4 and 20 g/min. An additional gas flow protects the melt bath partially from oxidation. The inner and outer parts of the nozzle are intensively water cooled, so that any hours of uninterrupted machining time are possible.

The cladding unit is designed by a modular concept. Using different adapters and adjustment items, it is compatible to CO2, Nd:YAG, and diode lasers. In addition, the head is easy to integrate into machine tools or robots.3 Two types of the nozzle allow the adaptation to special geometrical requirements of the workpiece. With respect to the nozzle function, the minimum focal length of the laser beam focusing optic is 150 mm.

Geometry Modifications and Tool Repair

Common laser techniques of repair in-clude the process steps:

- Importing 3-D data or digitizing the damaged area

- Data processing

- CNC programming

- Material buildup

- Finish machining

Usually, these manufacturing sections are sequentially carried out on different machines. The consequence is an increased effort of transportation and adjustment of the workpiece as well as of NC programming. Especially for the remanufacturing of parts, the time and cost of programming and adjustment often exceed the effort of the actual material replacement. Thus, the economy of the whole process is affected and some potential laser applications in this field cannot be realized because of financial reasons. To solve this problem, all necessary hardware and software were integrated into a CNC milling machine. Specially developed software connects laser, machine tool and additional components, so that the whole machining process takes place in one machine and in one clamping of the workpiece.4

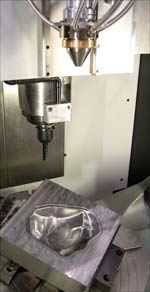

For buildup welding the beam of a 4.4 kW Nd:YAG laser was integrated into a five axes milling machine (see Figure 3). The focusing optic, combined with the coaxial cladding unit, is mounted at the Z-axis of the machine. The coaxial nozzle is an advanced version with reduced size and variable nozzle tips for a better adaptation to the given application and for easier maintenance. For this system, the diameter of the powder focus lies between 1 and 2 mm, depending on the powder type and powder feedrate. Powder feedrates from 1 to 50 g/min are possible (e.g. Ni base alloys).

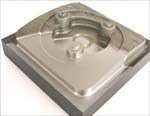

In Figure 4 an insert of an injection mold is shown. The structure is directly generated from the 3-D CAD data by multilayer cladding with STELLITE 21 powder. The accuracy of the material buildup is +0.3 to +0.5 mm. The finish machining is carried out by high- speed cutting (HSC) on the base of the same CNC data, which have been used for the generating process. In this way, no extra effort for programming of the milling machine is necessary. The generated structures are completely dense and flawless, even without intermediate machining.

To get an impression of the high accuracy of laser beam cladding Figure 5 shows two variants of tool repair. Moreover laser beam cladding embraces big advantages such as low dilution, good metallurgical bonding and low heat input.

Summary

Laser beam buildup welding has been established in the fields of repair and surface protection for years. CO2, Nd:YAG, and diode lasers up to 6 kW are in use for this purpose. To meet the special requirements of each application, robust and variably designed welding heads have been developed, which guarantee a stable and well-defined supply of the cladding powder into the laser induced melt pool. The coaxial nozzle design is important to get optimum cladding results. For industrial use, these nozzles must be easy to handle, the effort for maintenance should be low and spare parts like nozzle tips have to be easily to change. Often extra narrow and lightweight heads are required for complex applications in CNC machines or robots. Finally, the system integration of laser beam cladding in five-axis machining centers was proven.

Eric Stiles is with Fraunhofer USA, Inc., Center for Coatings and Laser Applications; Dr. Anja Techel and Dr. Steffen Nowotny are from Fraunhofer IWS, Germany; and, Prof. Dr. Eckhard Beyer is with Fraunhofer IWS and with the University of Technology at Dresden as Chair for Surface Engineering and Thin Film Technology at the Institute for Production Technology, Germany.

References

1Nowotny S., Scharek S., Naumann T., Gnann R., Beyer E., "Integrated Laser Milling Center for Complete Machining," The International Congress on Applications of Lasers and Electro-Optics, 2001.

2Groth A., Walz C., Naegeler S., Beyer E., "New Innovations in Diode Laser Cladding," The International Congress on Applications of Lasers and Electro-Optics, 2002.

3Nowotny S., Scharek S., Naumann T., Zieris R., Beyer E., "Laser Based Hybrid Techniques for Surface Coatings," The International Congress on Applications of Lasers and Electro-Optics, 2002.

4Nowotny S., Scharek S., Kempe F., Beyer E., "COAXn: Modular System of Powder Nozzles for Laser Beam Buildup Welding," The International Congress on Applications of Lasers and Electro-Optics, 2003.

Related Content

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreHow to Use Thermal Management to Improve Mold Cooling

A review of common mold cooling issues and possible solutions, including 3D printing applications.

Read More5 Hot Runner Tips for Moldmakers and Molders

Best practices for initial hot runner tryouts and effective preventive maintenance.

Read MoreLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreRead Next

Part Three of a Three-Part Series Laser Beam Hardening: A Flexible Tool for Wear Protection

The development of a new laser beam scanning system for the heat treatment of tool steels and various metals.

Read MorePart One of a Three-Part Series Metal Laminated Tooling-Process Chain

Results from laminated tooling testing show that this technology has the capability for an enormous reduction in cycle time via the integration of a conformal cooling system.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

_300x250 3.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)