New Era, Same Winning Formula

This company succeeds by staying up-to-date on technology and being willing to do a bit extra in the name of customer service.

Although 2015 is shaping up to be the best year ever for Carson Tool & Mold, the essentials of the company’s business philosophy haven’t changed. But that’s decidedly not the case for the technology employed by this Kennesaw, Georgia, tool shop. This year alone, the 24,000-square-foot operation added its first laser welder, and it will soon add its first injection press for sampling. Milling is more precise, sinker EDM is faster, and the company’s 23 employees are completing more operations in fewer setups than ever before, says Chris Myers, company president.

What has remained the same is a drive to not skimp on reinvesting in the business and to view mold manufacturing as the service that it is, he explains. Just as they did for his father and grandfather before him, these philosophies have informed his decision-making ever since he first started managing day-to-day activities about five years ago. Formally taking the reins after his father, David Myers, passed in April hasn’t changed that. “It’s been business as usual,” he says. “There’s just been a change of the guard.”

Undiscriminating Service

Given the diversity of Carson Tool’s workload, “business as usual” can mean anything but for certain segments of customers. For about a third of the shop’s work—packaging molds with as many as 128 cavities—supplying a certain number of spare, interchangeable inserts is standard industry practice. However, Myers and his team don’t limit such services to a certain segment of customers. Automotive industry tooling with far fewer cavities gets the same treatment, whether that means a few extra mechanical actions or a complete replacement stack for just two cavities. “We attack everything the same way, whether it’s a two-cavity fuel flange mold or a 64-cavity closure mold,” he says.

Past experience has shown that this practice can be well worth it, even if it means extra cost for the shop in the immediate term, Myers says. Typically, that happens because the company opts to manufacture spares even if the customer specifically requests to save money up front by avoiding this service. Although the components might never leave the shop, having them available makes Carson Tool a veritable white knight in an emergency situation. One recent example involved replacing a broken core pin with details that, in the absence of a spare, would have required more than 15 hours’ worth of wire EDM work at an expedited rate. “We end up carrying some inventory, and there is cost there, but it’s worth it,” he says. “In the real world, stuff happens, and having a tool go down can be catastrophic for an automotive manufacturer that’s running just-in-time production.”

Carson Tool’s policy toward spares evidences long-term thinking as well as the view that increasing customers’ profits is the best way to boost one’s own. This attitude has kept customers coming back and helped navigate plenty of tough economic times since the shop’s founding in 1945, Myers says.

Uncompromising Capability

During good times, leadership has historically poured profits right back into the company, and recent years have been no exception. The more the company ramps up technology, the greater its workload, culminating in the production of more than 50 molds in 2014. That’s about 10 more than Carson Tool manufactured in 2013 and far more than what had been the typical workload of approximately 35 tools per year, Myers says.

Whether success enabled adding new technology or the other way around is a question of chicken and egg. Regardless, Carson Tool makes a point to replace machine tools after 7 years if possible, and it never buys used. “Technology is always changing. We want the latest, and we want to know exactly what we’re getting,” he says.

One significant and relatively recent upgrade was Carson Tool’s move into linear motion technology. On the milling side, a Micron HSM 700 purchased in 2014 from GF Machining Solutions has dramatically improved capability. On one recent job, Myers reports that this machine helically milled 64 holes measuring only 0.036 inch in diameter with the same 0.5-mm-diameter end mill.

Although such precision is often sufficient to eliminate the need for slower sinker EDMs, those operations are faster than ever before, Myers says. That’s thanks largely to enhanced spark generator and other technology in the shop’s most recent EDM purchases: two AG60L Linear machines from Sodick, Inc., one of which produced a gas pedal mold cavity about three hours faster than its predecessor despite starting the burn about three hours later. What’s more, many features that once required multiple electrode sizes for roughing and finishing can now be produced with only one. Like the Mikron, these systems also feature linear motion technology. Adding to EDM efficiency is an electrode pull module in the shop’s Cimatron CAD/CAM software, which reduces electrode extraction time by 80 percent, Myers says. Along with 30,000-rpm graphite milling capability, this system has reduced cutting time from about two or three hours to 20 minutes for a typical electrode, Myers says.

When it comes to making use of this technology, strategies haven’t changed any more than the company’s overall business philosophy. Whenever possible, Carson Tool simplifies and streamlines the build by consolidating operations. The Sodicks, for example, feature larger worktables than their predecessors to accommodate additional, small parts for lights-out runs. Meanwhile, the Mikron is fitted with Carson Tool’s first on-machine part probe, and the company plans to incorporate similar technology on every new machining center. “Instead of taking blocks off for QC and possibly bringing them back again, we can probe contoured surfaces in the same setup, right after machining,” he says. “We’ll even throw workpieces from other machines on there if it’s open and the CMM isn’t tied up.”

Perhaps the most obvious example of consolidating operations is the go-to machine for the thousands of cores and other round parts the company produces each year for high-cavity closure molds. Although live-tool lathes have long been a staple on the shop floor, Mazak Corporation Quick Turn Nexus 200 MY CNC takes that concept a step further. Featuring a rotary tool milling spindle, Y axis and programmable tailstock in addition to the main turning spindle, the machine can produce features like keyways, engravings and even indicating flats for downstream EDM operations in a single setup. “We were doing far too many secondary operations—as many as three or four for some parts,” Myers says. “Now it’s one and done.”

A Bright Future

Some of the newer equipment at Carson Tool and Mold represents entirely new capabilities. The Eco 3300 laser welder from O.R. Laser facilitates finer touch-ups compared to TIG processes, largely because there is less risk of a heat-affected zone (HAZ) distorting the material. That translates to less outsourcing of repair and maintenance operations, as well as happier customers, Myers says, adding that the machine is particularly useful for medical industry work.

Even more important to the company’s future will be a new 400-ton injection press, Myers says (at the time this article was written, the company was still in negotiations for this particular piece of equipment). He expects sampling services to open the door to leveraging the company’s other competitive advantages—namely, a commitment to quality service and the expertise to take widely varying mold types from design through shipping. “Customers have been asking for this, and it’s going to open a lot of new doors for us,” he says.

Related Content

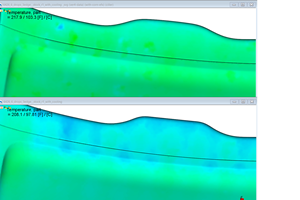

Quickly Troubleshoot New Molding Defect with Moldfilling Software

SyBridge Technologies analyst compares original, new Moldflow process simulation results, solves molding defect without tool needing to be taken out of production.

Read MoreHybrid Milling/Drilling Machine Reduces Total Mold Machining Time

MSI Mold Builders now squares, plus drills and taps eye-bolt holes on 50% of its tools in a single setup using a five-axis milling/drilling center with a universal spindle.

Read MoreControl Helps Push the Limits of Five-Axis Micro Mold Machining Accuracy

Toolmaker quickly meets the demands of critical medical device manufacturers with a new five-axis machine tool equipped with the right control technology.

Read MoreConsiderations for Mold Base Material Selection

Choosing the right material can greatly affect the profitability and cost of your application.

Read MoreRead Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

.jpg;maxWidth=300;quality=90)

_300x250 4.png;maxWidth=300;quality=90)