More Complex Tooling Solutions Yield Significant Cost Savings

Real-life scenarios describing how to make the optimum tooling strategy decisions—including early supplier involvement.

For high production molding, it’s clear that a higher cavitation mold will result in a lower part cost. However, how does one effectively calculate the maximum cavitation that can justify the capital equipment expenditure? What is the downstream impact on the part and mold design decision?

Key to success is early supplier involvement. Moldmakers have insight into a pallet of money-making approaches that the customer may not have. When a solid working relationship is formed between the mold builder and buyer, alternate approaches can be introduced—including highly compact cavitation designs, multiple parting line tools, and two-shot and spinning cube technology for in-mold assembly where savings and production can be maximized.

Spinning Cube Solution

Electroform Company was recently approached by a customer who wanted to use multiple presses and a gantry system to move the parts from machine to machine because of the complexity of the part. According to Wade Clark, Electroform president, the project involved some unusual geometry that would not allow it to be conventionally molded.

Looking at the project, Electroform proposed a combination of in-mold assembly and multi-shot tooling to produce the complete, assembled part in one machine. The customer was intrigued, if not also skeptical, and a design was created with a proposal in a couple of days.

“Once he saw the design he immediately recognized the benefits,” Clark says. The result was a more expensive tool incorporating spinning cube technology, but the long-term cost savings was apparent when two of three molding machines and the gantry system were eliminated along with extra steps in the assembly process. Additionally, faster molding times and reduced risk of contamination also add up to a lower piece part price.

“You can spend a lot of time and effort developing the projects and then get a negative reaction when the customer sees the price,” explains Clark. “These are complex systems and it takes hours to develop them correctly. The challenge is in fully understanding the customer and what their needs are so that the time, effort and outcomes pay off for all involved.”

In-Mold Assembly Solution

Bob Bordignon, director of business development at MGS Mfg. Group Inc., and John Berg, marketing director, share the following project details.

“We were approached by an existing customer to evaluate the potential of incorporating MGS multishot manufacturing technologies to a cap and closure program in order to produce a product that dispensed liquids and then resealed,” explains Berg.

The ultimate goal, Bordignon says, was to create a manufacturing system that encompassed the complete production of the part with all associated features: a threaded closure, foil insert for seal, and a second elastomeric material over the top of the foil that allows for entry into the vessel without removing the cap.

“We responded to the challenge by using our vertically-integrated, multiple-material technologies with our foil feed system to convert a standard molding machine into an insert/multi-material molding cell,” he says. “This in-mold assembly approach provided the finished product and eliminated the need for a 4-component post mold assembly machine. The ability to produce an assembled product out of the mold also eliminates the need for many metrology events. Once the process is established and qualified parts are being produced, there is no need for measurement at assembly contact points.”

The Rebuild Solution

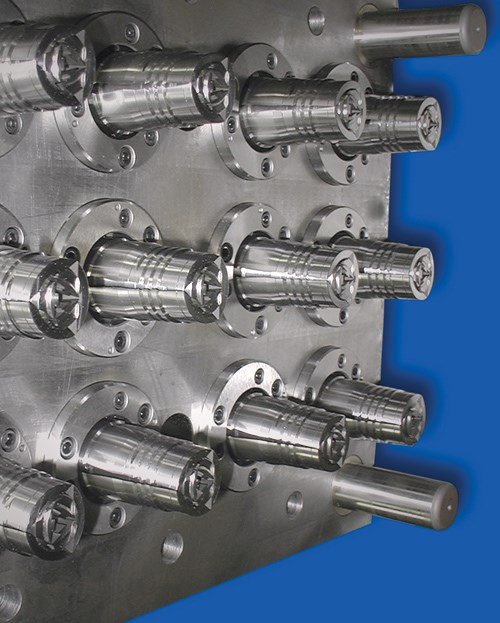

Phil Titherington, senior design engineer and toolroom manager at Mold-Rite Plastics, Inc., related details of a project concerning two unscrewing molds, each with years of production behind it, and further years ahead. Phil ‘did the math’ in order to consider retiring the unscrewing tools and going with a different approach.

“One mold was a 12-cavity tool to mold a 38mm cap and the other was a 24-cavity tool to mold a 24mm cap,” explains Titherington. “The whole idea with this project was to replace the old tooling with molds using new technology that would achieve faster cycle times, be simpler to operate and require less maintenance. I had just learned about the collapsible cores and thought they might present the best solution.”

Investing in new tooling proved to be a sound decision, according to Titherington, who conveyed that the new tools are faster to service and set up, and now, with a cycle time reduced by 50 percent, overall savings is at least $40,000 per mold per year.

96-Cavity Solution

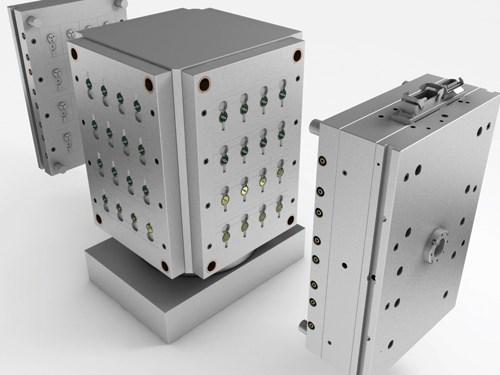

A customer of Janler Corporation was running three, 32-cavity cold runner unscrewing molds full time, but needed a much larger volume of production for a mature, inexpensive but vital part. The initial thought, according to Janler Vice President Charles Klingler, was to build two or three additional 32-cavity molds. The problem was that due to a complex unscrewing method and the use of cold runners, the molds required oversized molding presses.

“They asked us to start from scratch and provide some new options to management,” explains Klingler. Janler’s engineering team reviewed the molding process, current production issues and mold maintenance records. At first glance, stack molds looked like the perfect fit. A 64-cavity mold would run in the same molding press, producing double the volume at the same manufacturing cost. But it became apparent that these unscrewing stack molds would be very large and too complicated to maintain.

“We performed a filling and cooling analysis and found that the cycle could be reduced by as much as 50 percent, and we could place more cavities in the mold if we could eliminate the large cold runner,” Klingler explains.

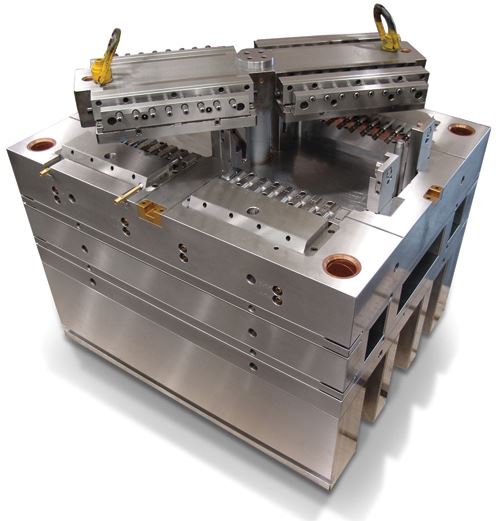

Ultimately, a single-face, hot runner, 96-cavity unscrewing mold was built that runs in a larger press, obtains a larger processing window and reduced the cycle time by 50 percent.

“This was one very expensive mold, but it is producing higher quality, more consistent parts at half the current manufacturing cost,” says Klinger. “It displayed an ROI that no one could ignore.”

Understanding Total Cost

These examples are just a few that show how a more complex tooling solution—which may cost much more than a traditional approach—yields an overall significant cost savings. To gain these savings, savvy mold buyers are involving their mold builders early, during product development, in order to ultimately find the most profitable solution.

Read Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More_970x90 3.png;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)