Maximize Machine Tool Potential With the Right Cutting Tools

Mold manufacturer seeks out cutting tools to match its machine tool technology, allowing them to operate at the highest levels of speed and precision.

#medical #automotive #casestudy

Quality Tool & Die, Inc. (Meadville, PA) manufactures molds, dies, fixtures and spare tooling for clients in the automotive, medical and electrical industries. Established in 1977, Quality Tool & Die was purchased in 2005 by five toolmakers that have 108 combined years of toolmaking experience. Strong business has led Quality to double their workforce since 2005.

“One thing that sets us apart,” says Brad McDowell, Partner at Quality Tool & Die, “is our willingness to accept low-run jobs that other tool shops would typically decline. We apply the same high level of quality workmanship whether it’s a single-piece order or a 60-piece production job.”

Featured Content

The Challenge

In order to stay profitable on a one- or two-piece run, getting the part right on the first try is critical. In addition to maintaining strict inspection procedures throughout the machining process, Quality Tool & Die aggressively seeks out machining technology that helps them to operate at the highest levels of speed and precision.

This philosophy led them to purchase a Makino S-56 machining center in 2006, and motivates them to implement cutting tools that maximize the machine’s potential.

Quality Tool & Die was struggling to find a cutting tool that could effectively mill 0.120” diameter holes 0.100” deep in a CPM 3V die plate. At 55HRC, CPM 3V has a lower hardness than other tool steels, but it can be more difficult to machine due to its toughness and abrasiveness.

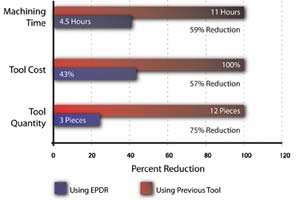

Each plate had 2,500 holes and was taking 12 end mills and up to 11 hours to complete due both to the reduced machining speed and operators having to constantly check the cutting tool for wear.

A Solution

Quality Tool & Die met with Hitachi Tool while attending a Makino Open House in MI where they discussed the CPM die plate application at length. Hitachi suggested its EPDR-TH corner radius end mills: a sub-micrograin tool designed to perform applications in hardened steels that were typically done by EDM.

Quality Tool & Die purchased several EPDR-TH end mills through their local cutting tool distributor, Kraeling Industries. With application advice from Hitachi, Quality Tool & Die was able to immediately employ more aggressive cutting conditions in the die plate application. The aggressive cutting conditions, combined with time saved from not having to constantly check the cutting tool for wear, allowed them to complete all 2,500 holes in less than 4.5 hours, a machining time reduction of 60 percent. All 2,500 holes required only three EPDR end mills, a tool cost reduction of 57 percent.

“We’re now able to run this job lights out,” says McDowell. “We’ll set the part up at night, and will return in the morning knowing that the job will be finished to spec.”

Following are three major features of the EPDR-TH that helped Quality Tool & Die achieve higher performance in hardened steels:

- Hitachi Tool’s TH nano-composite coating offers higher levels of heat resistance and hardness than conventional titanium-based coatings.

- The new neck design improves breakage resistance and gives the EPDR-TH end mills a longer effective reach.

- A 3- to 5-degree back taper on the peripheral edges allows them to avoid contact with the workpiece, reducing tool deflection, chatter and vibration.

Summary

Since the success of the EPDR-TH in the CPM 3V die plate job, Quality Tool & Die has employed Hitachi Tool’s cutting tools in a number of other applications throughout its shop. “Hitachi’s TH-coated end mills give us better surface finishes whether we’re milling 4140 pre-hardened materials, H13 or D2,” states McDowell.

RELATED CONTENT

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

-

Advantages and Disadvantages of Copper and Graphite Electrodes

Both copper and graphite provide approximately the same end result, so it is important for a shop to consider the advantages and disadvantages of each material in order to discover what would work best in their shop floor environment.

-

Selecting a Carbide End Mill for Aluminum Applications

Specific geometries and characteristics of a carbide end mill are required for efficient machining of aluminum.