Materials at NPE: New Solutions to Enhance Processing, Performance, Sustainability & Cost

NPE Wrap-Up

There was no shortage of new thermoplastics and additives covering the full range of end-use applications.

Share

Read Next

New materials and additives were plentiful at NPE2015, with new developments aimed at just about all the major industry sectors—packaging, consumer goods, construction, medical, electronics, and automotive. These developments address not just improved processing and end-use performance, but also economic and sustainability goals. The following report supplements preceding coverage in our March show preview and elsewhere.

HIGH-PERFORMANCE NYLONS

Italy’s Radici introduced both new materials and application advances with existing materials. Radiflam AR/250 HF 3003 Black, a 25% glass-reinforced nylon 66, is the newest addition to the company’s halogen-free, red phosphorus line of flame-retardant products primarily for the electrical market. This UL 94V-0 grade was developed for solar photovoltaic power applications—specifically, for support housings of solar inverters that convert DC to AC power. This growing market entails larger parts (i.e., 80 x 50 cm) that require weatherability with good surface properties and a minimal level of extractables to protect electrical components.

Radici has also moved ahead with its Radilon Xtreme XT6705, a novel nylon with an aromatic component, first introduced at K 2013. It has now been field tested by automotive OEMs and Tier 1 suppliers with the aim of replacing high-temperature nylons such as PPA and nylon 46 in turbo ducts and aftercooler end tanks. Such parts are often blow molded but are limited to 20% glass reinforcement, Radici says. Radilon Xtreme is offered in both injection and blow molding grades.

Following its introduction at K 2013, Radilon long-chain nylon 610 found use in truck air-brake tubing, fuel connectors, and fuel-vapor vent hose. Radici has now launched another new long-chain polymer, its first nylon 612 (joining other producers DuPont and Evonik). Radilon DT nylon 612 shows better chemical resistance than nylon 610 and is targeted for use in automotive and industrial fuel lines, clutch tubes, brake-boost pipes, and oil tubing, as well as water and gas filling tubing in the thermo-sanitary industry.

Ube America introduced to the U.S. its Terpalex nylon terpolymers for food-packaging shrink film. Produced in Spain, Terpalex is a nylon 6/66/12 that reportedly has FDA approval for applications such as shrink packaging of meat and cheese. It reportedly offers better shrinkability and thermoformability than nylon 6, allowing deep-drawability and potential downgauging. Ube is also working on new grades of nylon 6/66 copolymers that will have better aroma barrier and higher heat resistance, allowing longer sterilization cycles—such as 125 C for 3 hr—without loss of properties.

As reported previously, new material and application developments in nylons were also featured by BASF, DuPont, DSM Engineered Plastics, Invista, and Lehvoss North America.

VARIETY IN ENGINEERED COMPOUNDS

As reported previously, new engineered compounds at the show included advanced PP grades from RTP Company, PolyOne , and CTC Plastics. Examples were PP reinforced with very long glass fibers or with natural fibers, and custom grades with enhanced recycle content for automotive. There were also new automotive PC, ABS, and PC/ABS compounds from Albis Plastics.

Michigan compounder RheTech, now part of Sweden’s Hexpol AB (see February Starting Up), has made strides in creating a range of compounds with biobased content. The company has focused on PP compounds, under the RheVision brand, reinforced with natural fibers from flax, hemp, rice hulls, coconut shells, agave, and wood from pine, oak, and maple. Natural fiber content varies from 10% to 50%. Emerging commercial applications include household goods such as cutting boards, bowls, and toys, but also automotive parts.

The 2015 Ford F-150 pickup features an electrical bracket behind the instrument panel that is made from PP with 10% ground rice hulls, replacing talc-filled PP at 10% lower cost. The company has several projects with OEMs for interior and underhood applications such as fan shrouds to replace glass- or mineral-filled PP with natural-fiber compounds. Rhe Tech is also investigating the use of natural fibers in nylons.

BOOSTING PVC PERFORMANCE

PolyOne showcased its new Geon Bold PVC with dark, rich colors that reportedly stand up to the elements, especially heat buildup, without losing their color intensity or performance. They are targeted for outdoor living spaces and home exteriors that demand durability and require low maintenance.

Geon Bold formulations feature improved color retention in darker colors and a wider palette of colors that resist heat buildup, compared wih standard exterior PVC grades. Available in a range of gloss levels and use temperatures, they can be used to produce capstock for PVC, cellular PVC, or wood-plastic composite profiles, or straight PVC profiles and sheet. Capstock made from these materials is said to be a cost-effective alternative to painting, capping, or laminating with materials such as fluoropolymers.

New Luran styrenic grades from Styrolution were developed to enhance the performance of PVC building and construction applications. Among them is Luran HH-120 Q530, a powdered alphamethyl styrene-acrylonitrile (AMSAN) grade that has been shown to offer improved HDT in PVC compounds. Major North American manufacturers of siding, trim, and fencing have recently begun to use this material for heat management of panels produced in dark colors. Field tests show that this grade offers a very high HDT with a Vicat value of 248 F, higher glass-transition temperature (Tg), and lower weight. Its high miscibility is also said to allow for easy blending into PVC.

Other new Luran grades include S 797 Q530, an ASA powder for enhanced weathering resistance in PVC blends; S 777 ME, an ASA grade for high gloss and good extrusion processability; and S 747 R UV, an ASA said to provide excellent capstock coverage over foamed PVC cores.

As reported previously, new PVC compounds were launched by Teknor Apex and Aurora Plastics for weatherable capstock and exterior automotive applications.

BROAD RANGE OF TPEs

As we previously reported, several suppliers introduced new TPEs, TPVs, and TPUs. They included Elastocon TPE Technologies, Kraiburg, Teknor Apex and Polymax Thermoplastic Elastomers, with targeted applications ranging from consumer electronics and construction to medical and automotive.

In addition, Lubrizol Engineered Polymers showcased a new high-heat TPU formulated for superior abrasion and chemical resistance, along with excellent heat resistance and low-temperature flexibility. With its 125 C rating (vs. 105 C for other high-heat TPUs) and UL Yellow Card certification, Estane TS92AP7 is pegged as the next generation of TPU for cable jacketing and injection molded auto underhood components.

Also new from Lubrizol is Bio TPU, a line of TPUs made with renewably sourced materials. Available in extrusion and injection molding grades, they are said to perform equivalently to standard TPUs in hardnesses from 82 Shore A to 55D.

A new microcellular TPU foam that contains Lubrizol’s Estane TPU was also on show. Developed in cooperation with Trexel, BounceCell-X is a highly elastic microcellular material made with Trexel’s MuCell technology that reportedly excels in energy absorption and cushioning. In addition to light weight, superior long-term compression properties, and fast molding cycles, it is said to provide a thin, high-quality skin layer that adds aesthetic value, along with the typical TPU advantages of outstanding abrasion and cut resistance.

Meanwhile, PolyOne GLS Thermoplastic Elastomers launched an overmolding technology based on Versaflex VDT TPEs, developed for vibration and impact damping applications. This overmolding version of Versaflex VDT is available in 40-60 Shore A hardness, opaque and colorable, and is geared to consumer electronics, power tools, sporting goods, and appliances. It boasts excellent bonding to PP, nylon, and other polymers.

Star Thermoplastic Alloys & Rubbers unveiled its StarClear TPE 1000 for applications that require transparency, soft touch, and high-quality colorability in healthcare, electronics, home appliances, sports/leisure, and automotive. It is designed for vibration dampening in automotive and appliances, as well as maximum visual impact. It bonds to PP and is available in a number of grades and hardnesses (3-15 Shore A), including ultra-soft gels.

OTHER MATERIALS, APPLICATIONS

As reported in our March preview, Sekisui Plastics Co. introduced a new grade of its Piocelan moldable foam resin, engineered to meet stringent flammability requirements for automotive interior parts. A hybrid of styrenic and olefinic components, Piocelan T is composed of a higher heat olefin component than previous grades. Says Sekisui Plastics’s v.p. Thomas Pontiff, “Existing hybrid foam materials provide insufficient heat resistance for certain automotive interior applications. The new hybrid composition provides increased elevated temperature stability along with higher compressive, flexural and tensile strength and improved flammability.” Foam parts such as trunk spacers and insert cushions reportedly offer weight reduction of about 20-40%. Part size and cost also can be reduced due to the higher strength properties.

Other new materials included a portfolio of PEEK compounds from Techmer ES, Exceed specialty olefinic TPE for stretch films from ExxonMobil Chemical, and fiber-reinforced and low-volatility LSRs from Momentive Performance Materials. There were also some novel purging agents launched by Mould Plus, Sun Plastech, and RGL Sales.

ADDITIVES NEWS

Colorants figured prominently at the show, along with processing aids, compatibilizers, bioadditives, UV stabilizers, and flame retardants.

Clariant has revved up its North American offerings with new liquid color and additive masterbatches based on its HiFormer technology, launched globally in 2014. Liquid color has been integrated into Clariant’s ColorWorks design and technology center in West Chicago, Ill., so that the technology is an option to be considered early in the product-development stages.

With its tailored carrier technology and customized dosing and handling systems, HiFormer reportedly offers fast and simple color changes, maximum flexibility, and high color reproducibility. According to Peter Prusak, head of marketing for Clariant Masterbatches, the company has made huge advances in developing chemically balanced blends of pigments, additives, and carriers that extend the usefulness of liquid products beyond PET packaging and other standard applications. New alternatives to mineral-oil carriers have opened up applications in extrusion blow molding, where screw slippage was a chronic problem. Other components enhance flow for lower processing temperatures and improved dispersion and weld-line strength.

Teknor Apex’s Color Div. introduced impact-modified color concentrates designed to enhance the toughness of styrenic polymers while imparting the same bright colors available with corresponding unmodified concentrates. They are targeted to housewares, toys, disposables, and packaging. TekTuff PS concentrates (which follow last year’s launch of TekTuff impact-modified colorants for polyolefins) can boost falling-dart impact strength by 45% to 90%, depending on use level.

Meanwhile, PolyOne Color Matrix unveiled ColorMatrix Select, a Cloud-based liquid-color creation and supply service. It combines advanced liquid colorants, Web-accessed software, and automated dispensing technology to offer a complete package that offers brand managers, converters, and designers more control of their color development and supply chain. “We have customers who are taking this color development technology in-house to develop colors in minutes, allowing them to react quickly to market demands, achieve multi-regional consistency, and gain a competitive edge,” says Gary Fielding, marketing director.

Other companies with new color technologies, as reported previously, include Italy’s REPI with liquid colorants and Carolina Color with a patent-pending masterbatch technology that is said to generate the highest pigment-loaded custom colors in the industry.

Biopolymer supplier Metabolix has changed its focus from commodity to specialty applications for its PHA, according to Joe Shaulson, president and CEO. The company has several polymer modifiers based on its PHA for processing and performance enhancement of other polymers. At 3-4% use levels, one grade of PHA has been shown to be an excellent processing aid for PVC. An amorphous PHA grade has been employed at under 5% use levels as an impact modifier in PLA. End uses include cutlery, trays, bowls, and other compostable articles.

Other advances include PLA films with 20-30% PHA that have greater ductility, suitable for compostable film, larger trash bags for leaf collection or industrial use, and agricultural films.

As reported in the May Close Up on NPE, Genarex has a line of concentrated bioadditives that can be used as resin extenders at 10-30% use levels in PE, PP, PVC, TPEs, PLA, PHA, and PBAT.

Dow Packaging & Specialty Plastics showcased its new Retain Polymer Modifiers, a portfolio of compatibilizers that reportedly make it easier to recycle post-industrial barrier films without compromising performance or aesthetics. Based on a reactive, ultra-low-viscosity maleic-anhydride grafted polyolefin (an extension of

Dows’ Amplify TY tie-layer technology), these modifiers allow repelletized barrier films containing materials like EVOH and nylon to be more evenly dispersed into a polyolefin matrix. Dow sources confirmed that they have been able to produce multilayer PE films with up to 50% reprocessed barrier film trim in the core layer vs. only up to 5-10% possible previously.

Other news previously reported includes processing aids from Struktol and Arkema, flame retardants from Spain’s Tolsa Group, UV stabilizer masterbatches from Americhem, and mold releases from Stoner Molding and iD Additives. There were also new specialty conductive carbon blacks from Orion Engineered Carbons, synthetic and natural graphites from Imerys Graphite, and compatibilizers fromVertellus Specialties.

Related Content

How to Solve Hot Runner Challenges When Molding with Bioresins

A review of the considerations and adaptations required to design hot runners and implement highly productive injection molding operations.

Read MoreTechnology Roundup: The K Show Experience

Catch a glimpse into technologies for plastics, rubber, injection molding, hot runners, sustainability and more being showcased at this year’s K 2022.

Read MoreInternal and External Factors Continue to Impact U.S. Moldmaking

Sustainable growth remains in the forecast as economic conditions continue to progress.

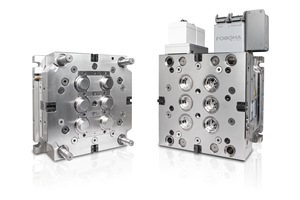

Read MoreMolds, Hot Runner Systems, Digital Technologies Highlight Sustainable Production

The Molding Solutions network at K Show displays Männer, Foboha, Synventive, Thermoplay, Priamus, Gammaflux and other external partners and their new or proven technologies for molding and moldmaking.

Read MoreRead Next

MATERIALS AND ADDITIVES AT NPE: Spotlight on Performance, Economy, and Sustainability

Lots of news in engineering thermoplastic compounds, TPEs, and purging agents, plus a wide range of colorants and additives.

Read MoreMATERIALS AND ADDITIVES AT NPE: Spotlight on Performance, Economy, and Sustainability

Lots of news in engineering thermoplastic compounds, TPEs, and purging agents, plus a wide range of colorants and additives.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

_300x250 1.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)