Liquid Silicone Rubber Molding Simulation

LSR and thermoset toolmakers are encouraged to make simulation an integral part of the design process.

Liquid silicone rubber is a versatile material and is preferred over other polymers especially in medical applications due to its biocompatibility, heat resistance, flexibility, self-lubrication, oil resistance and part quality. It is also used widely in automotive, electrical, and consumer products. Injection molding of LSR products is gaining in popularity as it enables high-volume production, fast cycle times, automated processing and manufacturing of intricate shapes.

Simulation of conventional injection molding as well as complex injection molding processes such as gas-assist, co-injection, over molding and sequential molding has become commonplace. This is unfortunately not true in the case of LSR molding.

The software technology has been there, but there has been one major drawback—lack of material data. The software is virtually of no use without the correct material data. LSR formulations are unique to each user, and it is nearly impossible for software developers to know what formulation the user intends to use in their project. Recent developments and agreements with material testing labs allow the user to characterize their custom formulations at a very affordable price. Furthermore, software providers are offering to characterize materials at no charge. These developments should make thermoset simulation more popular. This article discusses the applications of simulation in LSR and also thermoset molding.

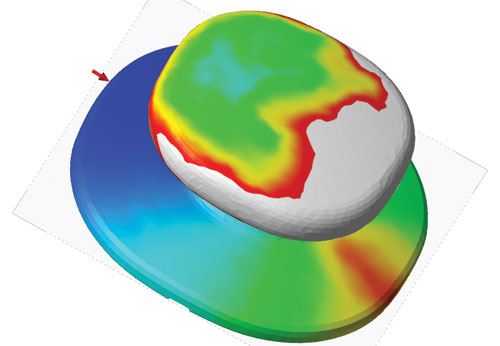

Find the Best Gate Location

Determining the number of gates and their location is a very important decision for the moldmaker. It determines how the part will fill and cure and will have a big impact on part properties. A wrong decision on gate location can prove to be extremely expensive to fix, and may require building a new tool.

Simulation allows the user to easily change the number of gates and their locations and review the results—such as pressure drop, fill time, cure % , shear rate, velocity, air traps and viscosity, to make a better decision (see Figure 1).

Eliminate Premature Curing during Filling

Premature curing during filling could result in an incompletely filled part. There are a number of reasons that can cause this problem: slow filling, long flow length, high mold surface temperature, wrong gate location, part thickness, etc.

The toolmaker can analyze the part and tool to check for premature curing (see Figure 2).

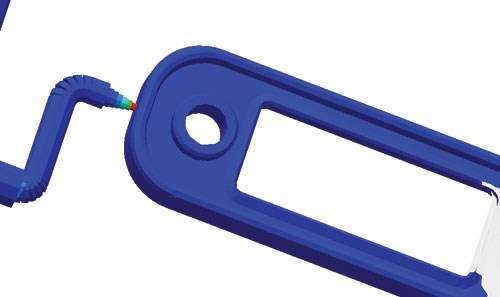

Detect High Shear Rates

High flow rates, small gates and runner diameters, and thin wall sections can lead to high shear rates in the tool. This causes a temperature increase, which may lead to premature curing (see Figure 3).

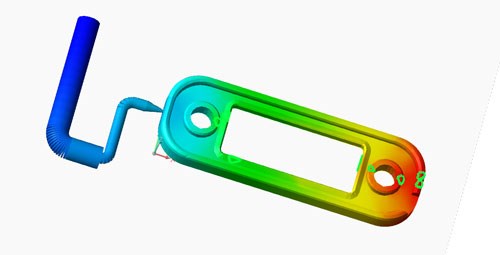

Determine Pressure Drop

High cavitation, long flow paths, small runner diameters, thin-wall sections and material viscosity are some of the factors that influence pressure drop. Excessive pressure drop can result in "maxing out" of the molding machine, which is not desirable. High pressure also leads to higher clamp tonnage requirements. Pressure drop can be calculated by simulation of the part and runner system.

The toolmaker can review the results and then make necessary changes to lower the pressure drop (see Figure 4).

Identify Air Traps

Air entrapment can lead to incomplete filling and degradation. A good venting design is required to avoid air entrapment. Simulation software outputs an air trap result.

The toolmaker can use this result to put vents in the necessary locations (see Figure 5).

Optimize Cycle Time

Cycle time is a very important parameter for a thermoset molder. High cure times basically mean lower profits. Cure time is the longest part of the cycle time and is influenced by material properties, part thickness and gate location.

The toolmaker can determine the cure time and cycle time by running a filling and curing analysis on the part. If the estimated cycle time is longer than the target cycle time, then the toolmaker can make changes to the part and tool design and then analyze the effects of the changes, to lower the cycle time without affecting part quality (see Figure 6).

Conclusion

Usually LSR and thermoset molding problems are detected during production. Stopping production to fix problems and retooling can be very expensive. Simulation helps the toolmaker optimize the tool design and identify potential problems before cutting the steel and can help reduce or even eliminate some of these problems. Simulation software products have become easy to use, fast and affordable. This coupled with free material characterization should encourage LSR and thermoset toolmakers to make simulation an integral part of their design process.

Related Content

Leading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

Read MoreCAM Automation Increases Mold Production, Quality

Mold builder switches CAM software package after 20 years to take advantage of innovative programming strategies that reduce mold machining programming and processing times.

Read MoreMold Innovations Power Unique Auto Lighting Elements on Hummer EVs

Diamond machining, electroforming of micro-optical inserts and modified latch-lock system help injection molds produce unique forward lighting elements.

Read MoreTolerancing in Mold Design, Part 1: Understanding the Issues of Conventional Bilateral Tolerancing

Mold designers must understand the location, orientation and form limitations of conventional tolerancing before changing to another dimensioning system.

Read MoreRead Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;maxWidth=300;quality=90)