Let’s Be Clear About Aluminum

Within the injection molding industry, a negative perception of aluminum for anything but prototype plastic parts persists, despite aluminum tooling being able to produce and run almost any resin that steel can, as well as produce millions of shots with unfilled resin with uniform results.

Today, aluminum tooling offers better quality with less scrap, faster cycle times, tight tolerances and a consistent process yielding reduced production costs. These results demonstrate a technological advancement in the way business is done in the plastics industry, and the range of possible applications for aluminum in injection-molded plastic devices is limitless.

In today’s market there is a momentum toward reshoring—the restoration of manufacturing in America—but let’s take it one step further by discussing an actual option that not only influences bringing back business, but is an alternative to steel tooling that affects how we manufacture.

According to reshoring.org, the mission of the reshoring initiative is to bring good, well-paying manufacturing jobs back to the United States by helping companies more accurately assess their total cost of offshoring, and to shift collective thinking from offshoring is cheaper to “local” reduces the total cost of ownership. There are plenty of reasons of to reshore, but there are also many advantages for all domestic suppliers to consider switching from steel molds to hybrid aluminum molds from alloys that provide advantages to the bottom line.

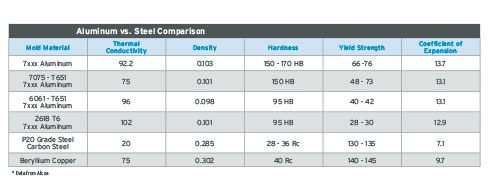

Aluminum has been around since it was first developed for aircrafts in the mid 1930s. The irony is that the 7000 series of aluminum is good enough to use for the framework on airplanes and the space shuttle, but is somehow so fragile it cannot be trusted to make a plastic component. This is primarily due to misunderstanding about the vast capabilities of this alloy. Following are some general facts about aluminum tooling:

• Aluminum alloys have a Brinell hardness range of 150 to 180, and a Rockwell hardness range of B82 to B87.

• Aluminum machines five to 10 times faster than steel, reducing finishing costs and lead times between 20 to 40 percent.

• Aluminum offers reduced machining time due to thermal and machining properties; less wear on cutters; fewer electrodes with faster burn time; and quicker polish times.

• Aluminum conducts heat nearly five times faster than P-20 tool steel, shortening production cycle times by 20 to 40 percent.

• Aluminum possesses better thermal conductivity than steel, offering a more consistent mold temperature, and resin flow equating to less warpage and higher yields, improving the molding process.

• Aluminum delivers critical advantages for OEMs as well, not just in mold and part savings, but in a faster time-to-market product.

• Aluminum tooling can provide millions of shots for products of unfilled resins, and hundreds of thousands of shots for resins such as glass-filled.

• Surface treatments for aluminum provide protection against abrasive materials, longer wear life and enhancement of esthetic surfaces.

• Critical dimensions and difficult geometries that require lifters or cam slides and Class A surfaces are just as successful with aluminum molds as they are with steel.

Example Part

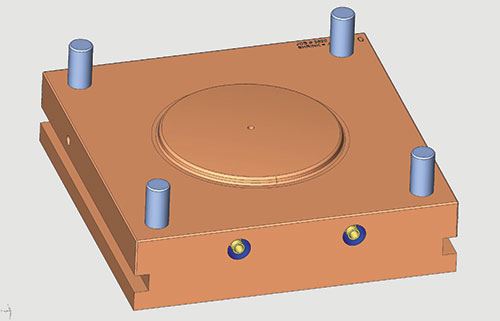

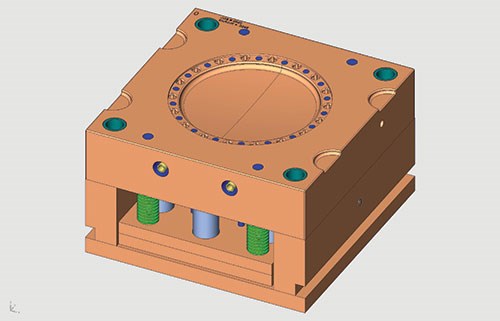

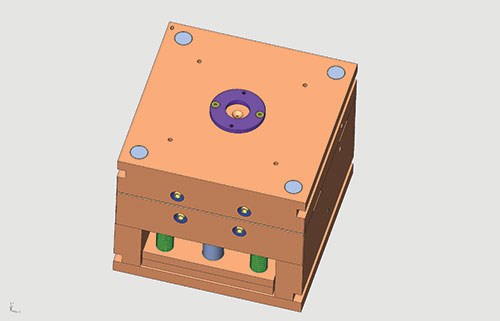

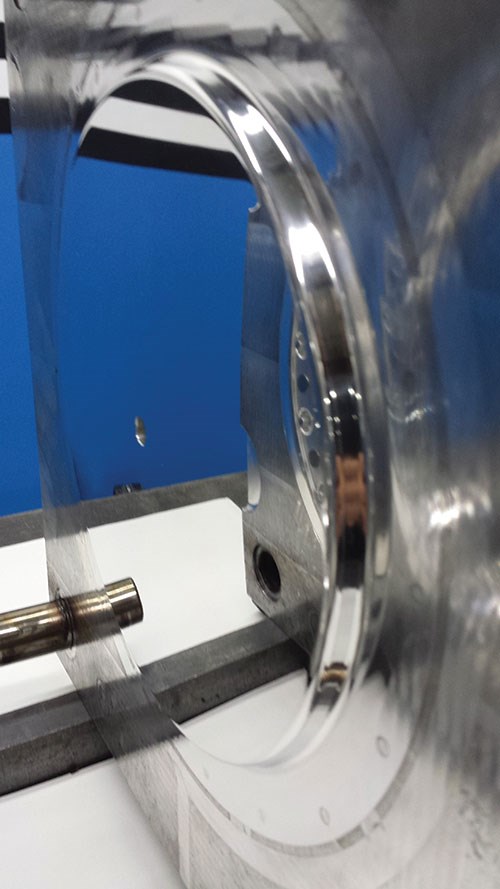

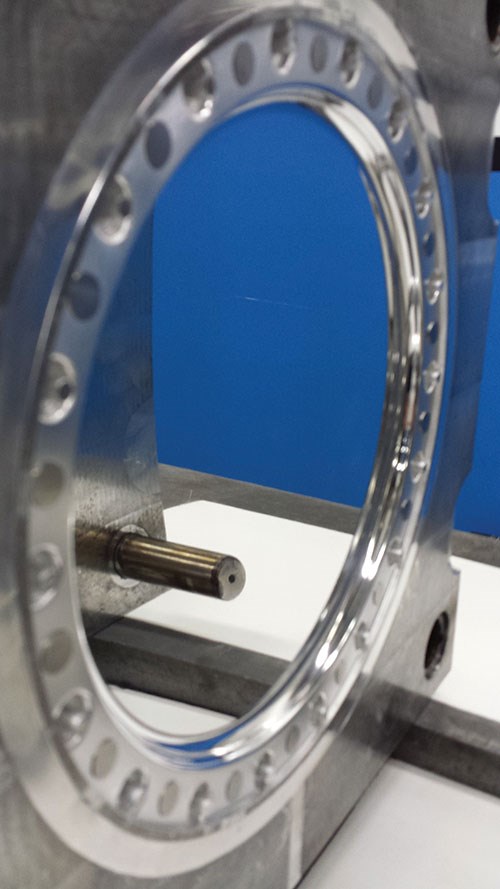

One highly misunderstood area in the plastics industry is the capability of aluminum tooling when it comes to Class A surfaces. A polycarbonate part is a good example of a high-quality, clear part manufactured in aluminum tooling. And yes, this is considered a Class A1 surface by industry leaders for high-gloss finishes. A part used by an OEM that produces parts for Disney World and the Bellagio Hotel fountains was produced from a 7075 aluminum alloy mold (see Figures 1-3).

Part Details: clear lens used for the consumer industry. Resin is a clear Mitsubishi polycarbonate iupilon ML-300-R591A, considered a special grade used for automotive head lamp lens components.

Part size: 1/2" × 9" diameter, 0.120" wall thickness, sprue-gated.

Mold description: one cavity; 16" × 16"; independent 7075-aluminum mold, hard-coated for Class A surface finish and 1,000,000-shot mold-life guarantee.

Mold completion: three weeks.

Cycle time: 32 seconds.

Class A surface finishes create optical components like prisms, light pipes, light guides and clear lenses from materials like acrylic and polycarbonate. Even with the highly aesthetic nature of clear plastic parts and the surface quality needed to achieve them, it is not impossible to expect the highest level of quality from aluminum tooling. If needed, there are surface treatments that can be applied to further harden aluminum tooling to ease the creation of difficult optical designs.

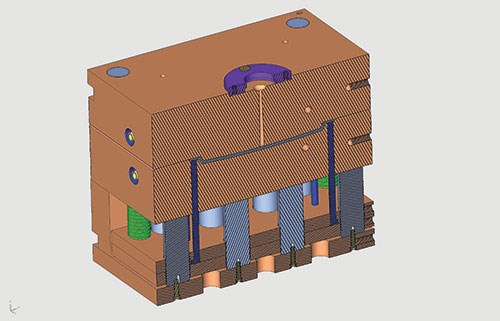

A level of difficulty does exist in working with translucent plastic resins. Both acrylic resin and clear polycarbonate have high melt points. They also have their own specialized process, which can get tricky if not handled by a seasoned professional, especially considering the intricacies and attention to detail involved with aluminum tooling. As it is, simple to complex optical designs come with their own set of distinctive best practices for high-production-quality parts. And speaking of complex designs and running acrylic resin, this part (see Figure 4) is an automotive light guide for an instrument panel component. The part is 3/4" × 3" × 8" with a contoured parting line.

Generally, prototype molders do not favor clear polycarbonate because of its high mold temperature requirements. Some say that it is impossible to get a Class A surface finish on an optical component, but it is done every day. You can run polycarbonates up to 300°F for optimal results. To create desirable parts, the temperature must remain constant in order to flow properly and overcome its inherent nature. With today’s improved grades of aluminum, there are more options allowing you to maintain higher temperatures without affecting the integrity of the mold material.

Summary

Most often the failure of an aluminum tooling project is in the incorrect selection of an aluminum alloy, along with poor design and poor tooling practices. Anyone considering aluminum must become educated on its benefits and characteristics. You need to choose the correct alloy material for your project needs. Equally as important is selecting a processor who knows proper tooling techniques.

Aluminum is not just for a prototype or the bridge to a faster product launch; it is a successful alternative to steel tooling with huge benefits that will continue to advance and influence the future of the plastics industry. Aluminum can and does produces Class A surfaces, so why not take the million-part challenge?

Four Key Points on Aluminum Tooling

John Engle of Honda America states, “After seven years of leading the project to have our Tier One suppliers adopt more aluminum molds, the biggest roadblock to getting our suppliers on board is getting rid of their outdated perceptions: ‘Aluminum is too soft,’ ‘limited tool life,’ ‘extra maintenance,’ etc., to which I reply, ‘Baloney!’. With more than 100 aluminum molds making production parts, we have yet to have a failure due to mold material. Several suppliers have ended their production runs with no issues, and no one has reported any problem with re-spotting or excessive maintenance. Our highest shot count is 2.1 million and that mold will not be out of service before 2015.

“I could write a book, but I will stick to a few key points: 1) Solid design is key. A poorly engineered product will always have problems no matter what the mold material. 2) Cost. Aluminum does tend to initially cost about the same as a P20 mold, however aluminum will out-perform P20 on reduced cycle times, making it cheaper over the run of the project. 3) Processing differences. You must either go with a knowledgeable tool shop or insist your production source work closely with a shop that can help them understand the proper processing parameters. 4) Weld works. For anything other than a catastrophic crash, there are new weld rods available for high-strength alloys, and, just like with steel, it matters who is holding the weld rod.”

Related Content

How to Correctly Size a Hydraulic Cylinder

This week Randy shares steps for correctly sizing a hydraulic cylinder on a mold.

Read MoreExploring ISO 9000 - Part 16 Control of Quality Records

A Series of International Standards for Quality Management and Quality Assurance. We begin 2022 with a review of Clause 4.16 Control of Quality Records.

Read MoreMaking Quick and Easy Kaizen Work for Your Shop

Within each person is unlimited creative potential to improve shop operations.

Read MoreSurface Finish: Understanding Mold Surface Lingo

The correlation between the units of measure used to define mold surfaces is a commonly raised question. This article will lay these units of measure side by side in a conversion format so that companies can confidently understand with what they are dealing.

Read MoreRead Next

Benefiting from the Properties of High-Strength Aluminum

When designed and engineered properly, high-strength aluminum has become a mainstream tooling material.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

_300x250 3.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)