Is CNC Machining Really Better Than RP?

Knowledge of both technologies is important for the selection of the right tool for the job.

When comparing the merits of rapid prototyping (RP) and CNC machining, opinions abound. RP and CNC machining both have staunch supporters that tout the benefits of their preferred technology. However, those who are familiar with both technologies generally agree that each has its own merits.

In the past 15 years, prototype development has changed significantly. In the early days, most RP technologies offered an obvious speed advantage, but were limited by accuracy and material property issues. Since the launch of RP, CNC has advanced, in part due to the competitive threat, to become faster while offering many well-known benefits. Likewise, RP has improved in areas such as accuracy, material properties and surface finish. As the technologies come closer in capabilities, the selection process becomes increasingly difficult.

Today, knowledge of both technologies is important for the selection of the right tool for the job. The following guidelines will aid in the selection process.

Materials

RP: Limited

Material development has come a long way. A broader range of materials and material properties are available. These now include metals, plastics, ceramics and composites. Yet, the selection is still very limited. And in most cases, properties do not exactly match those of machinable, moldable or castable materials.

CNC: Nearly unlimited

Machining centers are capable of milling nearly every material imaginable.

Maximum Part Size

RP: 24 x 36 x 20 in. (600 x 900 x 500 mm)

Although commercially available units may not be able to handle an instrument panel or bumper, the available build envelopes are suitable for the majority of consumer and industrial products. Should a part be too large for the system, it can be constructed in sections and glued. An important consideration is the impact of size on time. Larger parts take longer to build.

CNC: Large enough to handle aerospace parts

From small desktop units to large gantry systems, CNC machining can fabricate parts and molds of virtually any size. Practically speaking, size is only limited by the capacity of the available machine tools.

Part Complexity

RP: Unlimited

If a prototype can be modeled with design software, it is possible to build it with little impact on time or cost. The ability to quickly and cost-effectively produce complex parts is one of RP's biggest benefits.

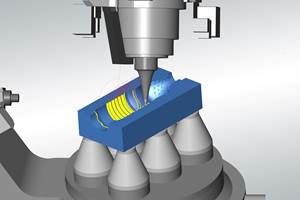

CNC: Limited

CNC machining must deal with every feature in a part, and this can add time and cost. As the complexity of the part rises, so do the number of setups and tool changes. High aspect ratio features, deep slots and holes and square corners can challenge the most expensive CNC milling machine. While a five-axis mill and some ingenuity can overcome challenging features, something as simple as an undercut can produce problems.

Feature Detail

RP: Varies

There are situations in which RP can produce features that CNC cannot. For example, RP can produce sharp inside corners and features with high aspect ratios, such as deep, narrow channels or tall, thin walls, ribs and posts.

CNC: Varies

For many features, CNC has the advantage over RP. Sharp edges, smooth blends and clean chamfers are among the details where CNC excels. This is especially true when evaluating detail in terms of accuracy and surface finish.

Accuracy

RP: 0.005 to 0.030 in. (0.125 to 0.75 mm)

While it is possible to achieve dimensional accuracy better than 0.005 inch (0.125 mm) on individual dimensions, 0.005 to 0.030 inch (0.125 to 0.75 mm) is the typical range of deviation. Accuracy is a function of the RP system and the size of the dimension. As a dimension increases, so does the inaccuracy.

CNC: 0.0005 to 0.005 in. (0.0125 to 0.125 mm)

With the right equipment, it is possible to machine at high precision. While CNC in general is more accurate than RP, precision is usually related to the cost of the machine.

Repeatability

RP: Low

Build any part on two different days and the results may vary. RP is sensitive to many factors that affect the quality of the prototype. Temperature, humidity, orientation and placement are just a few of the parameters that can affect the repeatability of the output.

CNC: High

CNC is much more repeatable than RP. If the toolpath, tool and materials are unchanged, the output is highly repeatable. Note, however, that environmental conditions and the human factor can affect results. Temperature and humidity, for some materials, can alter the outcome as can the accuracy of the machinist's setup.

Surface Finish

RP: Ra 100 to 600 in. (2.5 to 15 microns)

Without any secondary operations, some, if not all, surfaces will be rough. While RP has progressed to layer thicknesses of 0.0005 to 0.001 inch (0.0125 to 0.025 mm) for some technologies, the layer striations and stairstepping still affect surface finish. If desired, secondary operations can improve the smoothness to any level, but this can alter the dimensional accuracy of the part. Also, these operations can add time and cost to the project.

CNC: Ra 20 to 200 in. (0.5 to 5 microns)

Unlike RP, machining can produce surface finishes suitable for prototypes, patterns and tooling. As with RP, secondary operations (sanding, polishing) can further improve the surface finish, but they may adversely affect accuracy, time and cost.

Reliability

RP: Moderate

For most technologies, reliability increases as the product matures. The age of RP technologies ranges from one to fifteen years, which means that one can expect varying degrees of reliability. With less time and fewer resources, some of the RP manufacturers have not had sufficient time to refine the components of the systems to improve reliability.

CNC: Moderate to high

With more than thirty years of research and development, CNC is a mature technology that is dependable and reliable. Over the years, continuous improvement has eliminated system elements that diminish reliability.

Staffing

RP: Minimal

With the exception of secondary operations (benching), RP requires little labor. Within a few minutes, it is possible to prepare files for part production and start the build. During the build, there is little or no operator attendance.

CNC: Significant

CAM software applications have improved, but in most cases, they have not eliminated the need for human intervention. Machine setup and operation require an experienced machinist and it is rare that prototypes are made in a lights-out mode.

Skilled Labor

RP: Minimal

The technology is certainly not a minimum-wage position, but when compared to machining, the demand for highly skilled talent is much less. This is true in part because less labor is required. Additionally, RP has improved in ways that take the art out of the process.

CNC: Moderate to high

Machining takes skill, creativity and problem-solving abilities. From designing toolpaths and machining strategies to operating and monitoring the cutting, machining is the work of experienced craftsmen. With organizations getting leaner and the availability of machinists declining, there could be a lack of available resources for prototyping work.

Leadtime

RP: Short to moderate

With less labor, fewer steps and an insensitivity to design complexity, RP reduces leadtimes not only for the physical build, but also for the entire process. Overall, the RP process is more efficient in both time and labor. With RP, data can be received at 4:30 p.m. and parts delivered the next morning; this is unthinkable for CNC machining unless there is more than one shift. Yet, this does not mean that RP is the fastest for all parts.

CNC: Moderate

A lot goes into machining. Labor, toolpaths, fixturing, machine time and materials are required. The result is that many jobs will take longer than those done in RP. However, CNC can be faster when the design is simple and straightforward, and when high spindle speeds and feedrates are an option.

Practically speaking, the selection of the best technology may come down to machine time availability. Often, a looming deadline will override any accuracy or material property requirements. This, in turn, reveals the true measure of what is important to the prototyping application.

So, what is important to that next prototype - time, quality or cost? Balancing these factors requires a thorough knowledge of both RP and CNC. With it, informed decisions - not biased opinions - can be made for the selection of the best technology for the application.

Related Content

Control Helps Push the Limits of Five-Axis Micro Mold Machining Accuracy

Toolmaker quickly meets the demands of critical medical device manufacturers with a new five-axis machine tool equipped with the right control technology.

Read MoreDevelopments in High-Speed Machining Technology

There have been many exciting developments in high-speed machining relative to machining centers and controls, tooling and CAD/CAM systems.

Read MoreFive-Axis Graphite Mill With Automation Debottlenecks Electrode Machining

Five-axis electrode cutting enabled Preferred Tool to EDM complex internal screw geometry on an insert that otherwise would have had to be outsourced.

Read MoreCustomized CAM Strategies Improve Five-Axis Blow Mold Machining

The proper machining process and workflow can impact blow mold production, making your CAM software selection critical.

Read MoreRead Next

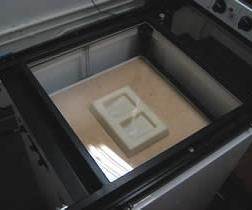

Printing Vacuum Forming Tooling with FDM

Combining the advantages of 3-D CAD and FDM technology, vacuum forming can be completed quickly, efficiently and cost effectively

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;maxWidth=300;quality=90)