Investing in a Five-Axis Future

This shop’s first five-axis machine offers capabilities that exceed its needs—at least for now.

Andreas and Joe Batz don’t expect five-axis machining capability to differentiate their shop for long. That’s one reason why the brothers chose a type of machine that—at least so far—isn’t often seen outside the sprawling, automated manufacturing lines of large automotive OEMs.

Their own operation, Sable Engineering, has little in common with the likes of General Motors and Ford. This mold manufacturing and engineering services provider deals mostly in lower volumes, and it rarely sees the same part twice. Nonetheless, about 85 percent of the shop’s production runs unattended. That’s why the Batzes appreciate the reliability of a machine built for demanding, high-production environments. Beyond sturdy construction, the machine’s horizontal, trunnion-type configuration and advanced features like thermal compensation add to the confidence required for lights-out operation.

Joe Batz says some features can seem like "overkill," but the brothers wouldn’t have it any other way. After all, Sable Engineering’s co-owners view their substantial investment as a pathway to competitiveness not just in the immediate term, but in a future in which five-axis capability is far more commonplace. "My personal view is that within five to 10 years, you won’t be able to compete at all without five axis," Andreas Batz says.

Branching Out

As an added benefit, support personnel and spare parts are close if the shop needs help. The machine, a G350 from Grob Systems, was manufactured in Mindelheim, Germany, but the builder maintains a 300,000-square-foot U.S. factory in Bluffton, Ohio. That’s just three hours’ drive from Sable Engineering’s facility in Port Huron, Michigan.

Although Grob has been building machines there for decades, it has historically focused on equipment for major automotive OEMs. Although the G Series Universal line is based on the same modular platform as production models, these standalone machines are targeted more toward smaller customers, and they’re now available through a significantly expanded U.S. and Canadian distribution network. That recent expansion included a 2014 partnership with Merrifield Machinery Solutions, the supplier of three of Sable Engineering’s five workhorse VMCs and now its first five-axis.

Just a few years back, Sable Engineering didn’t have any machine tools at all. Founded in 1999, the business initially focused on design services, mostly for the automotive and medical industries. The company grew steadily even as the 2008 downturn hollowed out the already dwindling supply of engineering talent and machining capacity in the Detroit area. Eventually, demand increased to the point where, as Andreas puts it, "We’d have been foolish not to buy equipment."

In 2011, Sable Engineering moved into its current manufacturing space and began to steadily accumulate equipment. Although the company has fewer than a dozen employees, their extensive knowledge has been critical to matching the output of larger shops, Joe says. Nonetheless, the Batzes reasoned that even the best machinists armed with the most sophisticated three-axis machining centers couldn’t always cope with increasing complexity in the shop’s core medical and automotive business. Nor would these assets be enough to diversify into aerospace work that, they say, is enjoying a renaissance of sorts in the Detroit area. The G350 has positioned the shop to achieve both goals.

A Twist on Five-Axis Construction

That’s primarily because the machine eliminates the need for sine plates or multiple setups. Top contenders for single-setup production include parts involving deep pockets, compound holes, undercuts, angled lifter channels and other complex features. Cycle times for some parts have been reduced by more than 50 percent, Joe says.

These benefits of five axis certainly aren’t unique to the G350. Yet, the configuration of this particular machine also offers its own set of benefits. As a trunnion-type, the machine can use shorter tool assemblies to access certain features without risk of the spindle head getting in the way. This improves rigidity. As a horizontal, it provides a great deal of space in the Y axis because the spindle approaches from the side of the workpiece rather than the top. Extra space enables accommodating larger parts. As an added benefit, the spindle retracts, turtle-like, back into the housing during tool changes. This avoids the risk of interference when repositioning the workpiece.

The shop takes advantage of the available space in other ways as well. For instance, the machine can be used like a fourth-axis boring mill by tilting the table to produce compound holes without a sine plate. Given that the machine features through-spindle coolant, this strategy is particularly useful for water lines and deep drilling of mold bases. Other applications involve fixturing multiple parts at once, particularly lifters and slides, on custom, three-sided tombstone fixtures. (The Batzes say a four-sided tombstone would limit the ability to machine compound angles.) That capability is particularly useful for lights-out runs, as is a 360-degree rotary B axis that enables flipping the workpiece upside down to dispose of any chips.

Finally, the brothers say few machines they’ve worked with are as precise as the Grob. As evidence, they cite experiences with blending corners. "Some machines just aren’t consistent," Joe says. "They’ll cut nice and straight up and down, but once you turn the head, it doesn’t blend out. In some cases, we’ve gotten complaints from customers because the finish was so good—we’ve had to emphasize that we’re still charging them the normal rate."

Lights-Out Confidence

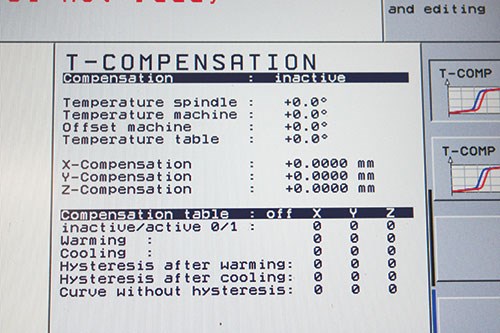

That precision is due to more than just robust construction. On any machine tool, ambient temperatures and the heat generated by machining can cause slight growth in the ways, spindle and other structural components. This can cause problems with accuracy and repeatability when jobs call for tolerances measured in tenths, as is the case at Sable Engineering. Equipped with a Heidenhain 530 CNC, the G350 not only tracks and reports the temperatures of various machine elements, but also compensates for growth or shrinkage, all in real time.

Ensuring precision regardless of temperatures in the workzone or broader shop adds confidence for lengthy lights-out runs, Joe says. It also saves time by eliminating the need to warm up or otherwise compensate manually for changing temperatures. "We can hit cycle start and walk away," he says, adding that the machine issues alerts or automatically shuts down if temperatures in the workzone, electrical cabinet or other elements get too high. Another feature useful for unattended operation is an automatic blow-off and brushing cycle that cleans cutters after every tool change. Tool changes also initiate an automatic touch-off cycle to check whether the cutter is broken and, if need be, swap to an alternative in the 40-slot magazine.

Prompt Service and Support

Topping off the machine’s capabilities is the knowledge that if something goes wrong, Grob can step in quickly to address the problem. Sable Engineering has already experienced this first-hand. Shortly after the machine was installed, it experienced a number of what Joe calls "oddball" problems, such as alarms going off for seemingly no reason. In response, Grob engineers in Germany logged into the machine remotely and quickly diagnosed the problem: the shop’s power supply. Shortly thereafter, a technician arrived from the builder’s Ohio factory to make the necessary adjustments. "We might not be as big as other customers, but they treat us just the same as everyone else," he says. "When we need help, they take it seriously."

Related Content

The Trifecta of Competitive Toolmaking

Process, technology and people form the foundations of the business philosophy in place at Eifel Mold & Engineering.

Read MoreSolving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

Read MoreThe Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

.jpg;maxWidth=300;quality=90)