Increase Mold Protection, Decrease Cycle Times

How to achieve optimal cycle times with the right plating option and the role of early involvement between molder/OEM.

Every molder and OEM has the same goal: to optimize production of quality parts and get their products to market on time. There are several strategies out there that will help to accomplish this goal, and many times the molder or OEM looks to his or her mold builder to lay the foundation for a successful project by knowing what is required throughout the mold building process and anticipating what is expected once that mold is built.

Similarly, the mold builder must take the same tack and look to his or her vendors to deliver what is needed on time and on the mark—there is no room for mistakes or long delays. The customer’s expectations behoove the mold builder to think 10 steps ahead on a project and offer viable solutions.

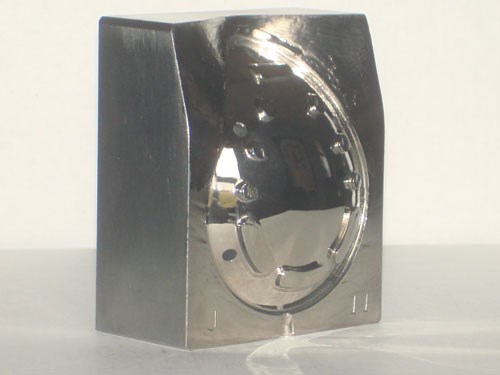

What’s the answer? Find a skilled, knowledgeable mold plating vendor who can help you not only increase protection for your customer’s most valuable asset, the mold, but who can also suggest ways in which a coating can decrease cycle times.

Peak Performance

Many shops have realized the advantages of using nickel-PTFE and nickel-boron-nitride coatings—including increased hardness and better release. For some, the enhanced lubricity also helped to significantly reduce cycle times.

Chris Hansen, who is a process engineer at Brandt Industries in Palatine, IL, relates the details of one such case: “Of a four-mold project we were awarded, we’ve built two molds that are manufacturing a product from blow molding grade polyethylene. Our biggest issue was that we had to run Saturdays and Sundays, 24 hours, to meet our customer’s high-volume needs.”

In addition to the extra hours, they were also encountering problems with sticking. Hansen explains, “No matter how deep the undercuts were on the B side, the part did not want to release from the A-side, and we couldn’t go any deeper on the undercuts. Rick Brandt, who owns our company, was not happy about any of this and we needed to find a solution.”

So they had a meeting to discuss how to run faster. Hansen say, “Because I’d had a lot of experience and success with mold coatings at a previous employer’s shop, I brought up the idea of using plating and Rick said ‘I’m tired of you talking about it. Let’s try it’.

“So we had the first mold plated with the nickel boron nitride,” he continues. “We set up the mold in the machine and the coating made the start-up so much easier. That blow molding grade PE is like concrete to melt. It was taking us an hour to start the machine and now it only takes about 10 minutes. We had no more sticking and right off the bat we cut 5 seconds off the cycle time. After the mold reached ambient temp, we were able to cut another two seconds off the cycle for a more than 25-percent improvement. After plating the second mold, we cut about 8 seconds off that cycle time for a 35-percent cycle time savings.”

These significant improvements in cycle times enabled Brandt Industries to stop running the molds on the weekends and still meet its customer’s volume requirements.

Planning and Preparation

Employing the most effective mold plating material begins with appropriate planning and preparation. Early involvement of one’s vendors is critical. Some of the most proactive mold shops have preferred vendor lists and spec books. Within those pages the polishing and plating vendor should be included—and consulted with before that first cavity is machined. With proper documentation about the mold, an effective surface treatment can be put into play with excellent results.

Masking is a key element when plating, and it takes time and is very detailed. It’s an integral part of the success of plating and is also a key step that, when done correctly, makes it possible for the moldmaker to assemble the job with the least amount of secondary work.

Bead blasting is also part of the preparation, and is used to clean the mold’s surface in order to maximize the adhesion of whatever plating process will follow. Highly polished finishes have to be protected during the bead blasting preparation process and also prepared by an experienced polisher prior to plating. These steps are not only important but they save time and money over the course of the plating process.

Additional Strategies

Shops also use different materials like beryllium copper for temperature control and reduced cycle times and production enhancement. It is often asked how a coating would affect the thermal conductivity of a tool. Coatings like nickel-PTFE and nickel boron nitride will not affect thermal conductivity, but will only enhance the protection and release properties of the tool, which in turn can result in reduced cycle times. Talk with your chosen plating vendor up front about every project, including the materials being molded, performance expectations, etc., to ensure the best production outcomes.

Related Content

What You Need to Know About Hot Runner Systems and How to Optimize Their Performance

How to make the most out of the hot runner design, function and performance.

Read MoreMachine Hammer Peening Automates Mold Polishing

A polishing automation solution eliminates hand work, accelerates milling operations and controls surface geometries.

Read MoreWhat is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read MoreRead Next

Surface Finish: Understanding Mold Surface Lingo

The correlation between the units of measure used to define mold surfaces is a commonly raised question. This article will lay these units of measure side by side in a conversion format so that companies can confidently understand with what they are dealing.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

.jpg;maxWidth=300;quality=90)

_970x250 3.png;maxWidth=970;quality=90)