In the Trenches: Mold Repair is a Challenge Worth Choosing

We developed this series to not only provide some camaraderie and encouragement—so you know that you are not alone in the trenches—but also to share some personal struggles, lessons learn and tricks of the trade. And, if in the course of this series we receive feedback, you will have done the same for me.

Performing mold repair day-in and day-out often seems like a thankless job. You weren’t specifically trained to do mold repair; you are more than likely working in a “less than state-of-the-art” toolroom; and you can never do the job fast enough—not to mention you’re a cost center not a profit center! Not only does it feel thankless, but lonely too here in the trenches. So we’ve developed this series to not only provide some camaraderie and encouragement—so you know that you are not alone in the trenches—but also to share some personal struggles, lessons learn and tricks of the trade. And, if in the course of this series we receive feedback, you will have done the same for me.

Some people have 20 years of experience; some have one year of experience 20 times over. With respect to full disclosure, I’m probably closer to the latter. I thought when I first got into moldmaking that there would always be tool makers working as long as we manufactured anything in the USA—and to a degree I’m still right about that. Then after a three-year hiatus from the trade, I returned to hear time and again, “We’re not hiring. All our work has gone to China.”

Time to rethink my strategy. What can’t be off-shored to China? Repair work? As long as we manufacture anything in the U.S. there will always be tool makers working. They may have to adapt to a different environment, but they will be working.

I had done a few short stints in a repair setting (three to be exact at the same place, hence the full disclosure of limited experience multiple times), and somewhere in the milieu of Round 3 is when I came to my eureka moment about repair work.

I don’t know that I ever heard a disparaging word about mold repair, but somehow I always got the impression that it was the red-headed stepchild of moldmaking. You know, the kind of tacit lessons you catch from your parents like your political leaning. We look at them and catch their values and generally end up following suit. They never said it was wrong to be a Democrat (or Republican) and never judged anyone negatively who was, but we just surmised from our experience that if it was good to be a Democrat then that’s what they’d be. I caught the same kind of lesson from the mold shops in which I worked. If repair was a good thing we’d be doing it, and we weren’t. And when we did, it was only because our arm had been twisted into doing it in the name of continuing good relationships to keep new (real) work coming in.

Well, live and learn. What do you know? Mold repair is a viable career option after all, and why not? People aspire to be automobile mechanics to keep cars running and maintenance mechanics to keep expensive production equipment running. Why not aspire to learn the skills to keep a $200,000 mold operating efficiently, longer? It’s a noble calling, rewarding, necessary and needed. Where is the PR person for this trade? Why are craftsmen resorting to it rather than actively chasing after it?

Perhaps it’s the glamour factor. Yes, you probably get to stay cleaner working on new tooling than you do while tearing down a gunked-up mold that was pulled out of production, but that’s not the glamour I’m referring to.

All the education is focused on machining (new build territory). All the technology developments are in the areas of better, faster design (CAD) and machining (CAM). All the investment? New equipment to build molds faster and education to train workers to use the new technology. The PR? What little is being done anymore, you guessed it—new build. In fairness, the overwhelming majority of jobs in this field are offered by companies that build new tools.

Still, the fact remains that there is and always will be, a need (and therefore, jobs) for skilled craftsmen to maintain and repair injection molds. I know firsthand the frustration of repetitive repair work. The blasé feeling of being so familiar with a mold that you can diagnose its condition over the phone. But there is opportunity for those willing to approach their craft with a little zest and zeal; to rise above the drudgery of routine repairs; to be more than just tool fixers. Become tool improvers and problem-solvers.

Not to denigrate new tool build in any way, but contrast the two specialties. Obviously no two shops are set up identically, but generally, at least in larger moldmaking firms, you have a house full of specialists—CNC guys, EDM guys, polishers, component makers, assemblers, etc. These guys are skilled craftsmen, many of whom have knowledge far beyond their area of specialization.

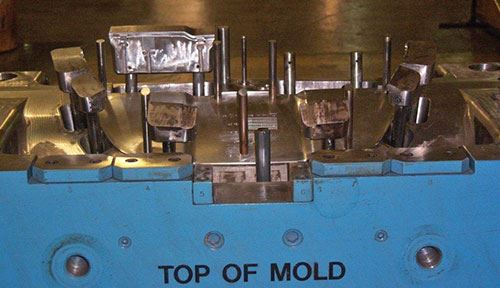

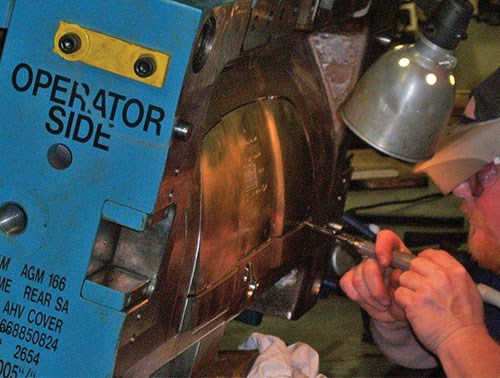

In repair, generally there is often a small handful of guys working in a minimally equipped toolroom who have to disassemble, analyze, clean, refurbish or rebuild, engineer, fabricate, fit, finish and possibly even verify tools under the pressure of production deadlines. Pretty glamorous, huh?

Coupled with all that glamour is the fact that in tool repair you get to see firsthand the effects of production wear-and-tear on tooling, and come to understand the necessity of knowing something about plastic processing. The knowledge base of many disciplines informs tool repair—from metallurgy to rheology and from machining to troubleshooting. It can be overwhelming or inspiring; the choice is yours.

Unfortunately the laws of supply and demand apply to more than just economics. Minimal demand for mold repair technicians results in sparse training resources. Some things require that you build your own curriculum and chart your own course toward the attainment of your chosen goal. Results of an internet search for “injection mold repair, training” will yield a few options to get you started. Mold repair is a challenge worth choosing. Choose wisely.

Contributor:

James Bourne is a tooling supervisor for SRG Global at its Farmington, Missouri, facility.

For More Information:

SRG Global

573-701-9123

jbourne@srggi.com

srggi.com

Related Content

Precision Welding Services Offer Rapid Turnaround Mold Repair and Reduced Molder Downtime

X-Cell Tool & Mold relies on outsourced, high-quality welding repairs from Lewis-Bawol Welding to ensure its customers' molds are back in production quickly and affordably.

Read MoreThe In's and Out's of Ballbar Calibration

This machine tool diagnostic device allows the detection of errors noticeable only while machine tools are in motion.

Read MoreQuestions and Considerations Before Sending Your Mold Out for Service

Communication is essential for proper polishing, hot runner manifold cleaning, mold repair, laser engraving and laser welding services.

Read MoreWhat You Need to Know About Hot Runner Systems and How to Optimize Their Performance

How to make the most out of the hot runner design, function and performance.

Read MoreRead Next

In the Trenches: Mold Repair

In this multi-part series of articles, contributer James Bourne, a tool repair supervisor and freelance writer, shares his own personal struggles in the business, as well as lessons learned and tricks of the trade garnered along the way.

Read MoreIn the Trenches: Mold Repair

In this multi-part series of articles, contributer James Bourne, a tool repair supervisor and freelance writer, shares his own personal struggles in the business, as well as lessons learned and tricks of the trade garnered along the way.

Read MoreDesign for Maintainability

It’s time to design features into molds that will provide for the easiest road to recovery.

Read More

.jpg;maxWidth=300;quality=90)

_300x250 3.png;maxWidth=300;quality=90)