Getting Quality Heat Treatment

Consultation with the heat treater regarding the material, mold configuration and processing variables is invaluable for maximizing tool life and cost efficiency.

A quality heat treating company offers not only heat treatment, but also a range of knowledge and skills that can improve mold life. Outsourcing heat treatment opens the opportunity to use the metallurgical and processing expertise of a commercial heat treater. To take advantage of this expertise becomes a matter of consultation in order to make the best heat treating decisions for the mold application. This is important for cost considerations. What can occur without correct processing and metallurgical knowledge is over- or under-processing a mold. Therefore, it is not just the heat treatment, but also consultation with a heat treater that makes outsourcing an important resource to consider.

Outsourcing also is a favorable option because of capital equipment costs for an in-house heat treating center. In addition to the furnace expenditure, other costs for an in-house operation include furnace start-up, utilities, maintenance and labor. Furnace costs and operation is becoming more of an issue because of the increased usage of vacuum furnaces - which demand a high level of technical competence.

Although specialized processing may favor the captive or in-house heat treating, because of the advances in materials science, this is not as true as it was in the past. As part specifications become more complex with more material choices, having alternative sources to utilize the optimum heat treating method becomes critical.

Most commercial heat treating facilities usually focus on a single metal treating process - air, vacuum or oil. Outsourcing heat treatment allows for the opportunity to utilize the various alternatives needed for different mold materials. Choice is an important factor for using a commercial heat treater. This is recognized among heat treaters that will refer customers' work to other heat treaters if the customized processing is not within their scope of expertise.

Therefore, consultation with the heat treater regarding the material, mold configuration and processing variables is invaluable for maximizing tool life and cost efficiency. A heat treater also can offer additional processes such as cryogenics and nitriding, which can significantly improve mold life.

Consequently, heat treaters - particularly when taken as a group - provide processing alternatives instead of being limited to just a particular furnace type or process. The goal is to match mold specifications with the best heat treating process.

Picking a Heat Treater

The challenge is to find the appropriate heat treating company for your specific mold application. This begins with a processing capability that results in clean molds with minimal distortion. Critical benefits are no temper-scale in the cooling holes and cavities and a mold whose dimensions are within requirements. Minimizing distortion is a challenge because of the internal stresses in the machined mold and the requirement to heat up to high temperatures for hardening, followed by quick cooling.

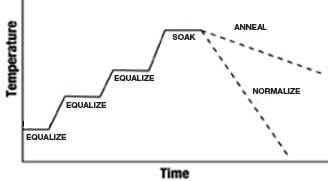

A logical selection for molds is vacuum heat treating - which offers clean, bright molds and minimal distortion due to controlled heating and cooling rates. To minimize distortion the ramping up or heating of the mold can be done in stages, that is, programmed preheats are performed so that the alloy steel can "relax" without becoming needlessly distorted. For this process to be successful, thermocouples must be in the mold in order to ensure tight control of the process. Work-controlled thermocouples will provide temperature readouts so the operator will know the mold temperature - thereby enabling precise temperature processing to minimize distortion.

Temperature control is equally important for cooling in order to minimize shocking the material and to provide proper microstructural transformation for hardening ability from the quench. Controlling temperature shock minimizes distortion. Vacuum heat treating uses controlled pressure quenching with inert gases - usually nitrogen - to cool the mold for hardness and tempering purposes. On the other hand, cooling quickly enough is critical in order to attain the proper hardness values.

Vacuum heat treating controls cooling through the use of pressure quenching and enhanced fan blower speed. The most common pressure quench range is two to 10 bar. Selecting the right quenching pressure is a function of material and part configuration. High pressure quenching combines the advantages of controlled cooling and the enhanced hardness values that result from a fast quench. The high pressure quench is necessary for larger mold cross sections, i.e., three inches or greater.

Vacuum heat treating is not the only heat treating method available for molds. It's important to consult with a heat treater to discuss the material, mold specification and its applications. Thereby, the best heat treating decision can be made for the mold application.

Successful Relationships

Good customer service is found when a heat treater values your parts as if they were his or her own. Added to this value is technical competence and communication that results in quality products and good turnaround.

Knowing that the heat treater is committed to good service will build trust. Trust will enable the moldmaker and heat treater to produce the most durable mold and should not be underestimated - it allows for the research and development of new heat treating methods with new materials to improve mold life.

Related Content

Precision Welding Services Offer Rapid Turnaround Mold Repair and Reduced Molder Downtime

X-Cell Tool & Mold relies on outsourced, high-quality welding repairs from Lewis-Bawol Welding to ensure its customers' molds are back in production quickly and affordably.

Read MoreSurface Finish: Understanding Mold Surface Lingo

The correlation between the units of measure used to define mold surfaces is a commonly raised question. This article will lay these units of measure side by side in a conversion format so that companies can confidently understand with what they are dealing.

Read MoreThe Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MorePortable Low-Heat, Non-Arcing Resistance Welder for Mold Repair

Rocklin’s user-friendly MoldMender Micro Welder delivers simple and cost-effective localized repair in-house with precision and versatility, enhancing mold and die durability and reducing disassembly and downtime.

Read MoreRead Next

Tool Steel and Heat Treatment, Part 1

An introduction to heat treatment for the moldmaker.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)