Electroform Company: Flying High

This high-precision, high-cavitation toolmaker soars as it thinks outside the box for innovative ways to attract new customers.

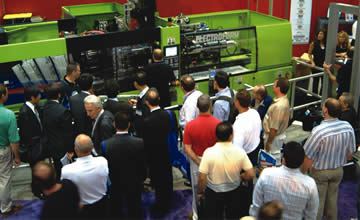

The secret to Electroform Company’s (Rockford, IL) success lies in the fact that over the years it has been able to adapt to a changing economy while continuing to fulfill the ever-changing needs of its clients. President Wade Clark also has had some innovative ideas along the way—evidenced at this year’s NPE show last June when the company actually ran a press with a fully interchangeable tooling system built for in-mold decorating and assembly, which produced a finished product right on the show floor.

Clark has always run with any opportunity when it came knocking. He was 22 years old when he was working at completing an apprenticeship program with a couple of local moldmakers. Clark then found he had an opportunity to get into the EDM business. He started Electroform in a local mold shop. Today, the company specializes in high-precision, high-cavitation, hot runner tooling. “We have completed many projects in insert molding and multi-shot areas,” Clark explains. “Clients come to us with complex projects. Our diversity attracts them—we perform everything from part design to the final product.” Additionally, Electroform provides turnkey operations—including automation and work cells.

On the Runway

When Clark opened his doors 18 years ago with one EDM machine, his specialty was in the aircraft industry, which afforded him a great deal of high-precision, close-tolerance work. “This set the tone and quality and inspection involved in our work through the present day,” Clark notes. Although Electroform ceased aircraft and custom EDM in 1991, that allowed the company to focus efforts on injection mold building.

During the first three months of being in business, Electroform moved from the local mold shop to his parent’s garage to a 1,500 square-foot space and added employees. In 1996, he upgraded to 3,000 square feet and retained eight employees. “We really took advantage of some rough times in the industry,” Clark recalls. “I was so young during prospering times in the industry and it was difficult to attract talented individuals, as I only wanted the best. I continued to be persistent and hired skilled machinists that we trained in moldmaking and now those individuals help set operational and quality standards that we abide by today.”

His perseverance paid off. In 1998, Electroform moved into its current loca-tion and has expanded to 30 employees. Several employees have been with the company for more than 10 years. “We have kept very busy,” Clark notes. “There are plenty of hours as we have never been slow.”

Innovation Takes Flight

About two years ago, Clark had an idea about his booth at NPE that had never been done before. He approached Glenn Starkey, president of Progressive Components. “Progressive loves being involved in highly complex tooling,” Starkey states. “The higher the stakes—the better. So when Wade approached us with his idea for this NPE mold, we were enthusiastic toward it from the start.” Clark then took the time to go through the patents to make sure the company wasn’t infringing on anyone’s intellectual property before meeting with his engineers to begin designing the mold.

The part design and prototyping was completed in four weeks, the mold in seven weeks, and automation at four weeks and the integration of the cell took two weeks. The total development of the system took 17 weeks. At that time, Engel had already scheduled all press builds for NPE 2006, but after meeting with Clark, had a change of heart. “When Wade requested a machine in a timeframe that we considered relatively short when preparing for a show, we were a little hesitant,” explains Steve Elliott, machine sales manager for Engel. “However, since we are a leader in multi-component molding machinery and automation, we saw potential and a need in the industry for what Wade was proposing. We completed a 200-ton tiebarless machine with non-operator side parting line secondary injection and integrated Engel robotics in the timeframe required. Wade and his team working with our service technician did the rest.”

At the show, Electroform ran a two-shot Engel press equipped with the company’s proprietary, fully interchangeable tooling system specifically designed and built for in-mold decorating and assembly. A Heitec hot runner system was used in the tool. The fully automated cell produced decorated and completely finished functional race cars, assembled in the mold from six different parts.

“Our partners didn’t realize what we would be producing until the show,” Clark notes. “Everyone involved was very thankful to us and they showed a lot of appreciation. Not only did it do a lot for us, but for our partners as well. Anytime you come out with a new technology that is cutting edge, everyone involved seems to benefit. A lot of our new programs are teaching our clients how to take their products to the next level utilizing the latest in technology. For us, NPE was a large risk financially, but proved to be successful.”

Assembling a Crew

Besides being on the cutting edge of technology, Clark says that one of his greatest achievements has been putting together the group of people that comprise Electroform. “I can bring in new tooling projects, buy any program, automation or equipment, but if I don’t have talented people, I have nothing,” Clark states. “Seeing the appreciation they have for their coworkers, their environment and for technology—combined with the quality of tools they produce and the customer feedback I receive—is validation of a job well done. Money is not the driver for me; it’s the satisfaction of doing things correctly and the pride of delivering an excellent product to our clients. You can certainly see the pride that is taken in our company atmosphere. I am very fortunate to be in a great industry that I am passionate about and have surrounded myself with the people I have. This has been a very satisfying accomplishment and I look forward to finding more that fit our culture.”

Clark notes that Electroform’s stability lends itself to employee loyalty. “Overall, people are looking for a quality, stable job and we offer a track record of stable hours from the beginning,” he notes. “We have outstanding benefits, and pay them well, and they get to work in one of the best manufacturing environments in terms of technology, cleanliness and employee attitude. We give them something to be proud of.”

Spreading Its Wings

With sales up 125 percent over the past three years, Clark seized the opportunity to expand Electroform’s operations. “Our new, 3,000 square-foot facility in South Carolina has just opened,” he says. “We made the shop a mirror image to the shop here to give us more flexibility. My longest term employee of 16 years will be running that facility and we will be hiring six to seven machinists/toolmakers.

“The point of this facility is to help our clients in the southeast by offering them a convenient location to service their tooling,” Clark adds. “We also have an engineering office in Clearwater, FL, which we are looking to expand soon. Another venture we are looking into is purchasing an injection mold shop in an area that will make sense to us. It will be a company that will complement us and may need a technology boost, or perhaps the owner will need some succession planning."

In the short term, Electroform is on the hunt for some quality employees. “We will continue to look for talented people to support our growth so we can keep developing in a balanced manner and continue to rise to the next level,” he concludes. “We are out to do one thing: build a good product while keeping our clients happy.”

Related Content

CAM Automation Increases Mold Production, Quality

Mold builder switches CAM software package after 20 years to take advantage of innovative programming strategies that reduce mold machining programming and processing times.

Read MoreConsiderations for Mold Base Material Selection

Choosing the right material can greatly affect the profitability and cost of your application.

Read MorePrecision Welding Services Offer Rapid Turnaround Mold Repair and Reduced Molder Downtime

X-Cell Tool & Mold relies on outsourced, high-quality welding repairs from Lewis-Bawol Welding to ensure its customers' molds are back in production quickly and affordably.

Read MoreHybrid Milling/Drilling Machine Reduces Total Mold Machining Time

MSI Mold Builders now squares, plus drills and taps eye-bolt holes on 50% of its tools in a single setup using a five-axis milling/drilling center with a universal spindle.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

.png;maxWidth=300;quality=90)

_300x250 4.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)