Electrical Discharge Generator Breaks New Ground

A brand new EDM generator achieves a cutting speed of 400 mm}/min, or 37 square inch/hour, for the first time in the world, and achieves the feat of marrying the integrity of the surfaces machined with a high cutting speed.

EDM wire cutting has been characterized by extraordinary technical and economic development since its industrial beginnings during the 1970s. From the technical point of view, its progress has not been steady, but rather in the form of technological leaps forward interspersed with periods of calm. In less than 30 years, machining speed has been multiplied by a factor of 15. The increase in cutting speed has been marked by the following main stages:

- 1973: 30 mm}/min, or 3.72 square inches/hour.

- 1990: 200 mm}/min, or 18.6 square inches/hour.

- 2002: more than 400 mm}/min, or 37 square inches/hour.

Breaking the 400 mm}/min barrier was long considered virtually impossible by leading EDM specialists.

The Wishes of Users

There are several wishes most frequently quoted by the users of EDM wire cutting machines. Without being exhaustive, these wishes or demands can be classified into three main categories.

First, machine as fast as possible, but with no special demands as regards to surface finish. This case is encountered above all in the following activities:

- Machining of prototype parts.

- Dental and medical industry (roughing of dental implants and various types of prosthesis).

- General mechanical engineering, etc.

Second, machine as fast as possible, but without deposits on the surfaces machined. This case is encountered above all in the following activities:

- Cutting of electrodes for EDM die sinking machines.

- Cutting work in general. Toolmakers frequently wish to make cutting tools (dies, punches) of medium precision in one single pass and also want the machined surfaces to be free of any deposits, so that the cutting tool can be used straight away.

- General mechanical engineering, etc.

Third, machine faster, but with no alteration of the surface machined. This case is encountered in a wide and varied range of industries, such as:

- The carbides industry, for producing powder compacting dies and sintering dies.

- The medical industry, for reasons of biocompatibility.

- The mechanical engineering industry and the wood industry, for sharpening chisels, mill cutters, etc.

- The electronic industry, for producing cutting tools for integrated circuits.

- All industries that make high-precision cutting tools for the mass production of parts, etc.

It should be stressed that the great majority of users are small companies that can work in all three categories just mentioned, depending on the orders they receive. Consequently, the great majority of users require a universal machine.

These few examples clearly show that there is a great diversity of cases and user demands. Certain wishes are a priori incompatible, for example: machine much faster while still obtaining machined faces free of deposits or while perfectly respecting surface integrity.

Yet this is the challenge that engineers have overcome by coming up with a generator that achieves the feat of conciliating the integrity of the surfaces machined with a high cutting speed. This is a step forward of decisive importance in the technical development of EDM wire cutting machines and especially their potential scope of utilization.

The Generator

A brand new generator of electrical discharges has achieved a spectacular technological breakthrough in crossing the barrier of 400 mm}/min - or 37 square inches per hour.

This cutting speed is obtained thanks to the new shape of current pulses. The generator machines the part by using as its tool discharges of extremely high intensity at a rate of several million per second. Such strong pulses have never previously been produced and mastered.

It has been accepted to date that the more energetic the discharges, the bigger the craters resulting from each discharge, with the result that the surfaces of the faces machined would be rough and the layer recast by the spark erosion would be thick. But in this case you get quite the opposite effect. This new generator perfectly respects the integrity of the surfaces machined while at the same time cuts extremely rapidly.

Another important feature of this generator is its universality. The programmable sparks can adapt to a wide range of materials such as steel, tungsten carbide, boron carbide, titanium, aluminum, PCD, composite materials, exotic materials used in aeronautics, etc.

Although the sparks or discharges are perfectly programmable, nature has it that not all discharges are equivalent. If it did not have the facility of processing and acting in real time on each discharge through specific software or hardware actions, this generator would never have been able to attain its present performances. Instead, a system controls and acts on the discharges.

The System

Without going into the topology of discharges, which have specific properties and which often have undesirable effects on the workpiece or wire, can be mentioned the following types of discharge:

- Short circuits by contact (the wire is in contact with the face of the part).

- Metallic short circuits (the machining debris has created by fusion a metallic bridge between the wire and the part).

- Discharges that, without a specific action, would cause the wire to break.

- Discharges that do not have an erosive effect.

The system that works with the new generator is an ultra-fast data acquisition system that analyzes each discharge individually, processes the data and gives the order to the generator or other units of the machine to perform the appropriate actions. To be more concrete, you can say that it is the brain of the process. It makes it possible to cut at high speeds without wire breakage and with the guarantee of preserving the integrity of the surfaces machined. In cases where the geometry to be cut includes fine details, there is another unit that deals more particularly with the obtaining of precise details. It supplies the system with the appropriate supplementary information.

EDM Wire

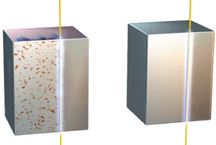

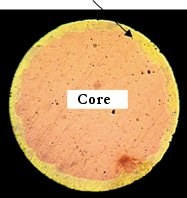

In addition to the system, experts have developed a wire to make full use of the potential efficiency of the generator (see Figure 1). This is a copper wire coated with a diffuse layer of zinc. It is essentially in the zinc layer that the craters caused by the discharges will develop.

Because zinc is a metal with a low point of fusion and has a high latent heat of fusion and a high evaporation heat, the formation of craters absorbs a lot of energy. Therefore, only the remainder of the energy transmitted becomes diffused in the core of the wire.

As a result, the core only heats up to a small extent, and it becomes possible to work with much higher discharge frequencies than with a wire without a zinc layer, and hence to machine more rapidly. This zinc layer forms what might be called a thermal shield.

In Figure 2, the zinc layer has virtually disappeared in the direction of the wire feed - the thermal shield has successfully played its protective role in the core of the wire, which has remained practically intact.

High Cutting Speeds

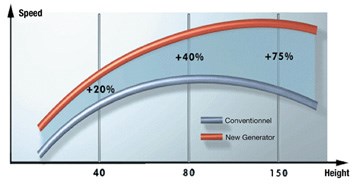

It is by using the generator - assisted by the system and EDM wire - that the cutting speed of 400 mm}/min is attained under the real industrial conditions of a wire machine (see Figure 3). In these specific conditions, and for parts of simple shape, this speed can even be exceeded.

The timesavings is obtained when machining all heights, but is particularly great when machining parts of great height.

It is above all in general mechanical engineering applications that the high cutting speeds of 400 mm}/min and higher will find their main uses. In many cases, traditional mechanical milling will be challenged more and more by wire machines with their flexibility and rapidity of setting up, combined with their ever increasing cutting speeds and the possibility of fast cutting of parts of great height.

There also is a large increase in speed when the new generator is used with brass wire, as can be seen in Figure 4, and in particular when the workpieces are very high or very long (punches, moveable parts in molds, plastic extrusion, etc.).

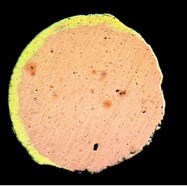

Absence of Deposits

Experienced users will observe straight away after machining their first part at top speed with this generator that, compared with parts machined with a conventional generator, the part has a different aspect, as can be seen in Figure 5. Measurements prove that, although the usual deposit that occurs after roughing with standard generators still exists, it is about four times thinner. If roughing is done at a speed slightly lower than the maximum speed, the deposit only amounts to a few microns. This means in practice that electrodes and cutting tools of average precision can easily be machined in one single pass.

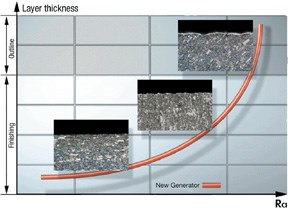

Timesavings in Finishing

The fact that the deposit is thinner and more regular after roughing enables the number of finishing passes to be reduced (see Figure 6). This is because the machined face after roughing already has physical and metallurgical properties that are very similar to those of the basis material.

In addition, the property of only slightly altering the machined face is repeated with every finishing pass. Furthermore, the generator produces neither any electrolysis nor electrochemical corrosion from roughing through to finishing.

This new generator perfectly meets the needs of users who want to enjoy fast machining, yet who demand machined surfaces that are absolutely unspoiled by EDM.

Conclusion

With the new generator, the most severe demands and the most wide-ranging needs of EDM users are met. Through its universality and exceptional performances, this generator will enable users to strengthen their position in their present activity and to become highly competitive in markets that they have not yet tackled.

Related Content

Surface Finish: Understanding Mold Surface Lingo

The correlation between the units of measure used to define mold surfaces is a commonly raised question. This article will lay these units of measure side by side in a conversion format so that companies can confidently understand with what they are dealing.

Read MoreThe In's and Out's of Ballbar Calibration

This machine tool diagnostic device allows the detection of errors noticeable only while machine tools are in motion.

Read MorePredictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

Read MoreRead Next

Achieve More with Twin Wire EDM Technology

As wire costs continue to increase, twin wire will be recognized as a strong tool for fine tuning wire EDM performance and reducing cost.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More.jpg;maxWidth=970;quality=90)

_300x250 3.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)