Checklist for Long-Reach Toolholders

Moldmakers hoping to avoid problems such as chatter, poor tool life and molds that fail quality control muster need to consider a variety of factors when selecting a long-reach toolholder.

Deep pockets in mold cavities can be a real bear to machine. Toolholder length-to-diameter ratios are stretched to the max, and cutting forces are high. Without the right toolholder, these conditions are the perfect storm for chatter, poor tool life and molds that fail quality control

muster. Moldmakers hoping to avoid these problems need to consider a variety of factors when selecting a long-reach toolholder.

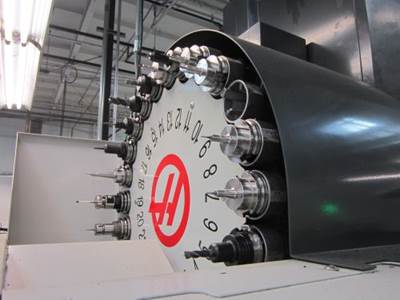

Hydraulic clamping. Compared to collet chucks and shrink-fit holders, hydraulic chucks have a smaller nose diameter relative to the tools they hold. This is critical, as these holders allow you to reach further into the mold without interference, which is something that’s becoming more important with the increase of five-axis mold machining and its longer reach requirements.

Vibration damping. Hydraulic chucks also dampen vibration and provide better surface finishes than competing methods. For those concerned about potential out-of-balance issues due to a hydraulic holder’s one-sided set screw design, don’t be. A good-quality hydraulic chuck runs every bit as true as a shrink-fit holder, without the hassle and expense of a shrink-fit heating and cooling machine.

Holding power. One area where shrink-fit has the upper hand is speed. For example, a hydraulic chuck may be rated to 35,000 rpm. Above that speed, centrifugal force tends to pull hydraulic fluid away from the holder’s internal gripping gland, causing some loss of clamping force. However, when used within its recommended operating range, a hydraulic toolholder offers holding power comparable to shrink-fit, with superior runout and repeatability. On average, a good shrink-fit holder has about 0.0003-inch runout, while a hydraulic chuck offers 0.0001 inch or better.

Gripping strength. For optimal gripping, the use of cutting tools with shanks ground to H6 tolerance or better is recommended. That’s because gripping force drops off exponentially as shank diameters decrease. Consider a typical ½-inch-diameter end mill. With a shank measuring exactly 0.500 inch, both shrink-fit and hydraulic holders provide 100 percent of the available gripping strength. But with shank diameters in the lower range, minus 0.0005 inch, a shrink-fit’s gripping force drops by roughly 60 percent while hydraulic loses around 40 percent.

Maintenance level. Toolholders should be cleaned regularly with products designed to keep toolholder bores clean and dry. Using a certified test bar for regular checks of a toolholder’s gripping force is recommended, as this gripping force tends to drop off when toolholders approach end of life. Don’t forget about the machine tool as well. The clamping capability of the spindle drawbar should be routinely verified against manufacturer’s specifications by using a properly calibrated drawbar force gage.

Balance methods. Balance is critical in long-reach milling applications. For best results, always balance toolholders as a complete assembly. Many tooling providers pre-balance their holders at the factory, but this is often inadequate, especially for long-reach applications. CAT and BT-style holders should be balanced with the retention knob and cutting tool in place, and HSK holders with the internal coolant tube installed.

Hydraulic toolholders are precise devices, so proper care is essential. Operators should never engage the hydraulic clamp unless there’s a cutter in place and never use Weldon-shank tools because both will damage the hydraulic mechanism. Finally, holders constructed of H13 tool steel offer the longest service life.

Related Content

Considerations for Mold Base Material Selection

Choosing the right material can greatly affect the profitability and cost of your application.

Read MoreMaintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

Read MorePlastic Prototypes Using Silicone Rubber Molds

How-to, step-by-step instructions that take you from making the master pattern to making the mold and casting the plastic parts.

Read MoreMachining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreRead Next

Streamlining Setups at Seescan

In addition to new equipment, this captive shop’s transformation involved implementing strategies to make the most of existing resources.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

.jpg;maxWidth=300;quality=90)