Avoiding the Pitfalls of Overseas Tooling

The keys to managing offshore tooling are solid communication, an onshore team of mold experts, part samples before mold shipment and onshore molding.

For buyers of injection-molded or blow-molded parts, the decision whether to use tooling based overseas or in the United States can be complicated. It’s true that molds made in the U.S. are generally higher quality. It’s also true that governmental regulations sometimes require that the tooling be designed and built in the U.S. Other times the decision related to the tooling source is based on personal beliefs. Most often, it comes down to balancing cost, speed and quality.

At CY Plastics, we create molds for our own injection and blow-molding operations in western New York. We also source molds from qualified tool shops, both in the U.S. and overseas. We strive to choose the right approach for the situation and to manage the process to meet the customer’s needs using any one of these approaches.

When Offshore Tooling Makes Sense

The simplest molds are the best candidates for overseas tooling, especially if they are large or feature multi-cavity layouts. With more challenging molds, the benefits of offshore tooling are not as clear. Some characteristics that make a mold “challenging” include:

• Moveable mold components (slide action)

• Multiple cavities

• Thin walls or fine details in the part

• Complex textured parts

• Complex geometry such as compound angles and threaded features

• Gating restrictions due to part geometry

• Tight dimensional tolerances on the part.

There are overseas moldmakers capable of making more challenging molds, however, it takes time to identify and develop these partners.

The more expensive the mold, the more dramatic the cost savings if it is built overseas. For example, a large, multi-cavity mold with slide action might cost around $75,000 if it is manufactured in the U.S. versus about $30,000 plus some $10,000 in air freight if built in China. A savings of $35,000 is hard to ignore.

Offshore tooling becomes even more attractive with short lead-time requirements. For example, the Chinese tooling industry is huge, with seemingly limitless manpower. A U.S. molder can typically get a Chinese mold manufactured within 4-6 weeks and have it shipped a week later, if the molder understands the logistics. It is possible to receive a mold within 4-6 weeks from U.S. toolmakers, but the molder will usually incur expediting fees on top of the higher base price for the mold.

Getting Optimal Results from Overseas-Sourced Tooling

When sourcing tooling from overseas, these specific actions can help ensure the best results:

1. Concentrate on a few good relationships. Building good relationships with partners is critical to outsourcing success. This means evaluating the many potential source shops, narrowing the list down to the few best candidates, and then building very strong relationships with one or two selected partners. If you work with the same vendor over many projects, you should learn how to effectively communicate what you want in a mold, what your partner is capable of and how you can best work together.

2. Communicate. There are basic good practices for communicating technical information to any vendor, and these become especially critical when communicating across different languages. One essential tool is a comprehensive specification form, completely filled out with specific details, including all the materials of construction. Another communication technique is the use of detailed graphics with text labels to call out areas of concern. A visual tool conveys information more quickly and clearly, and is less open to misinterpretation than a paragraph of text in any language.

Pay attention to differences in terminology. Material, surface finish, texture, color, mold construction and gate type are all examples of critical specifications that may mean one thing to you and something different to an overseas moldmaker. For example, steel grades may be called out in DIN grade rather than the AISI grade commonly used in North America, so that 420SS (AISI) may be quoted as 1.2083 (DIN).

Communicate “upstream” with the part designer as well. As a moldmaker, we mitigate many of the risks of overseas tool sourcing by addressing design for manufacturability (DFM) with the customer at the quoting stage. We discuss any tolerances that may be problematic and whether they are essential to part performance. By clearly understanding the part requirements, the moldmaking team can suggest changes to improve manufacturability and achieve the design intent.

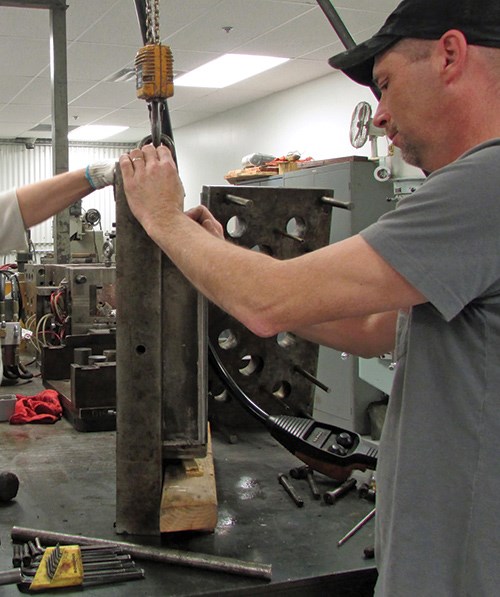

3. Have a U.S.-based tooling expert manage the entire project, from mold design through part production. Ideally, both a tooling expert and an experienced plastics molder will be involved. These experts will understand how the design will affect the usability, durability and maintainability of the mold, as well as the characteristics, quality and manufacturability of the molded plastic part.

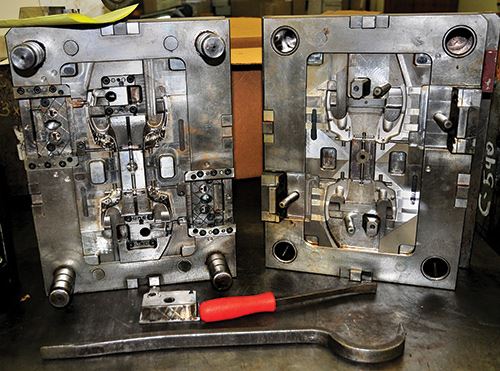

In our experience, overseas molds are usually designed to be as simple to machine as possible. For example, when a core pin is required, it may be designed as solid in the mold impression, although an inserted pin would make adjustments and repairs easier. To minimize mold maintenance and repair issues, write detailed specifications that address known wear areas and require that critical areas be designed to be replaceable.

4. Sampling is critical. Get part samples and verify mold function before shipment of the mold is authorized. Once a mold is paid for, it may be extremely difficult to recover any money if the mold is not acceptable. If sample parts are not within specification, work with the moldmaker to make adjustments until the samples meet requirements.

When there is not time for multiple revision cycles with the offshore tooling vendor, again, it is helpful to have an onshore team of tooling experts. Although it’s definitely preferable to have parts delivered to print before a mold is accepted, a U.S.-based team can assess whether any changes are needed and how easily it could make those adjustments. If the team determines it can do the final grooming fairly quickly to get the mold to specification, this opens up more options for meeting quality and time-to-market requirements.

5. Bring the mold home. More and more, U.S. buyers are sourcing tooling from overseas and running the parts in the U.S. Bringing the mold home keeps it secure and helps protect intellectual property. It also makes the mold easy to access for quick production—same-day, if necessary.

Whether the mold is made in the U.S. or overseas, however, if the parts themselves are to be molded in the U.S., there are additional reasons to work directly with the tooling design team at the plastics molding facility. First, molds wear out over time, and certain material resins have inherent wear properties. If the plastics molder has skilled moldmakers and a well-equipped tool shop, maintenance or repairs can be completed on-site with minimal disruption to production schedules. Second, if the customer makes a design change to the part several years down the road, the on-site tool shop should be able to easily make the changes because it is familiar with the mold design, the part design intent and the capabilities of the production equipment.

Having a U.S.-based tooling expert manage the process is key to achieving these benefits and avoiding the pitfalls of offshore moldmaking.

Related Content

Women Impacting Moldmaking

Honoring female makers, innovators and leaders who are influencing our industry's future.

Read MoreTransforming Moldmaking into Digital Industrial Manufacturing

Moldmaking and digitalization is at the core of this global industrial manufacturing company’s consolidation and diversification plan.

Read MoreHow to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

Read MoreEditorial Guidelines: Editorial Advisory Board

The Editorial Advisory Board of MoldMaking Technology is made up of authorities with expertise within their respective business, industry, technology and profession. Their role is to advise on timely issues, trends, advances in the field, offer editorial thought and direction, review and comment on specific articles and generally act as a sounding board and a conscience for the publication.

Read MoreRead Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;maxWidth=300;quality=90)

_300x250 1.png;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)