September 2007 Issue

September 2007

Features

Featured articles from the September 2007 issue of MoldMaking Technology

Harnessing EDM Technology for Micromoldmaking

For moldmakers considering making their foray into micromoldmaking, a solid understanding of the benefits of new EDM technologies is necessary to make the transition as smooth as possible.

Read More

RP/RT Technologies Offer Speed, Consistency for Consumer Products Molds

The constantly changing world of consumer products warrants molds that can be produced quickly while still maintaining high quality.

Read More

Selecting the Best Toolholding Solution for Your Shop

A look at ER collet systems and a review of the properties to look for when making your toolholding purchase decision.

Read MoreThe ABCs of the R&D Tax Credit

Here’s what you need to know to see if you qualify for this often lucrative tax credit. Chances are, if you build complex molds, you are entitled to reap the benefits.

Read MoreLeveling the Playing Field?

If you are able to make price part of the issue, and not the only issue, you have a better chance to show your customers why working with you will be their best solution.

Read More

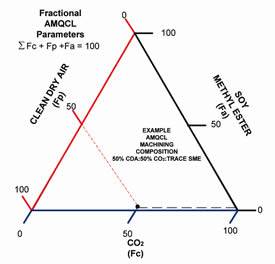

Machining with Advanced CO2 Machining Spray Technology

Advanced CO2 machining spray technology delivers robust, high performance and adaptive cooling and lubrication for challenging mold machining applications.

Read More

Accu-Mold, Inc.: Experienced with Success

This moldmaker relies on veteran employees and immerses itself in the industry to get the job done right the first time.

Read MoreTechnology Test

As you know, we’ve been covering additive fabrication (rapid prototyping) regularly throughout the year to keep you updated on what’s going on in that world and how it will affect you.

Read More

Gage Calibration: When in Doubt Send It Out

A discussion on how gages get calibrated, who calibrates them and where it is performed.

Read More

Five-Axis Machining: What Are The Benefits and How Can You Achieve this Capability?

The alternative you choose to achieve five-axis machining benefits will be application driven and can have a significant effect on your bottom line.

Read More

Waterjet: A New Spin on an Old Trade

Waterjet technology helps moldmakers evolve and become more versatile.

Read More

Arm-Wrestling Unique Measurement Problems

A look at the advantages of a portable coordinate measuring machine in mold design and manufacture.

Read More

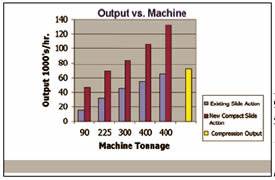

Slide Action Technology—Higher Cavitations in Smaller Machines

A new stack mold design—Compact Slide Action Mold Technology (CSAM™)—has been developed to maximize productivity without the need to invest in larger molding machines.

Read More

_300x250 1.png;maxWidth=300;quality=90)