August 2008 Issue

August 2008

Features

Featured articles from the August 2008 issue of MoldMaking Technology

Always Comes Back to the Mold Builder

How important is mold maintenance and repair to the mold manufacturer? Very. Because it always comes back to the moldmaker.

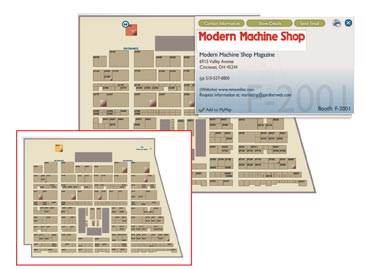

Read MoreHow Online Communities Can Help Your Business

Let’s look at how online communities (OCs) can have a positive impact on—and support—your business’ strategic development and initiatives. The cultural impact of OCs on the future of manufacturing can’t be overemphasized. As young students, engineers and manufacturers enter and move up the ranks of manufacturing companies (including yours) they’ll be bringing with them expectations to communicate in the ways they are most comfortable.

Read More

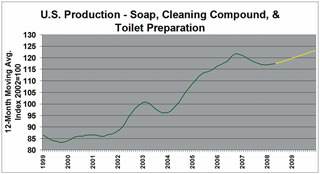

High-Precision Molds Pay Off for P&G

Procter & Gamble stresses speed, repeatability and long life to maximize return in commodity production.

Read More

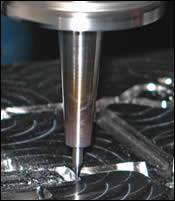

Machining Madness: Advances in HSM

The industry’s demand for higher quality, faster turnaround times and lower prices in the last decade has resulted in dramatic improvements in high speed machining as well as controls and spindles.

Read More

Electrically Actuated Valve Gates: An Emerging Hot Runner Technology

Electrically actuated valve stems promise more control, cleaner actuation, closer pitch spacing, higher quality gates and reduced maintenance.

Read More

Alan Petrucci: An Industry Icon

Not content to rest on his laurels, this moldmaking veteran continues to immerse himself in the business for nearly half a century.

Read More

Automation, Innovation Chart EDM’s Course

Advances in EDM technology—including increased automation and combining machining processes to get the job done as efficiently as possible—help EDM stay afloat and keep moldmakers successful.

Read More

A Workholding Solution for Gun Drilling

Gun drilling is one area for which moldmakers have been slow to accept permanent electro magnets, which can reduce workholding and toolholding setups by 50 to 70 percent.

Read MoreEveryone Is Welcome

Account managing is the fine art of balancing the needs and expectations of your customer with the skills of your company personnel.

Read MoreThe Seven Ds of a Buy-Sell Agreement

My client handed me his 13-year old buy-sell agreement. The business value, specified as a fixed amount, was about 3 percent of the current market value. Any problems here? First, the value is not current and too low. Attempts to enforce the contract would result in litigation. Second, the IRS will not accept the low value for estate tax purposes. Third, since this agreement is not current, the funding for the buyout does not exist. Either the buyer or the company must come up with funding or it’s very likely all or part of the business will have to be sold to a third party.

Read MoreDetermining Maximum Mold Cycle Counts

Ongoing data collection and visual inspection of tooling and parts is the only method that will allow you to balance maximizing tooling life, production capability and mold reliability.

Read More

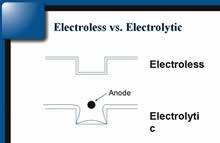

Build-Ups for Maintenance: Benefit or Band-Aid?

When is providing build-ups on tooling appropriate and when is it just a band-aid on a problem that could lead to more extensive repairs later?

Read More

.jpg;maxWidth=300;quality=90)