August 2007 Issue

August 2007

Features

Featured articles from the August 2007 issue of MoldMaking Technology

Partnering for Success: One Builds, The Other Repairs

A moldmaker and a shop that specializes in mold repair/engineering unite their specialties to increase capabilities and compete globally.

Read More

Maintenance Data for Processing Technicians

Data that processors need and what they should collect.

Read More

Custom Mold & Design: Making History

This longtime moldmaker’s molds boast long running times and millions of cycles thanks to the best equipment and dedicated employees

Read More

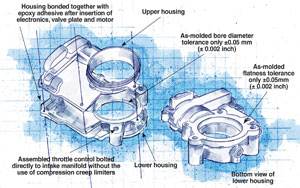

Pushing the Traditional Design Envelope with Hybrid Modeling

The complementary relationship between existing CAD technology and digital shape sampling and processing has led to a process called hybrid modeling, which combines the strengths of scan-based measurement with feature-based modeling.

Read More

New PET Bottle Standard May Boost Business for Moldmakers

A rule to lightweight preform necks and closures could require more than 1,000 new molds.

Read MoreTen Pointers for Better Mold Production

Although the criteria and the technology used to produce molds have changed dramatically in recent years, the basic rules for developing a mold that meets the original design criteria, and functions effectively, have not changed at all.

Read MoreAnswering the Call

How do we better educate ourselves, our shop employees and the industry overall?

Read More

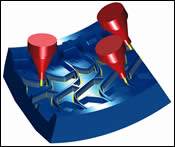

Hot Runner Application Review Leads to Successful Processing

Successful application of a hot runner in the molding environment requires detailed analysis of gating styles, resin and molder expectations.

Read More

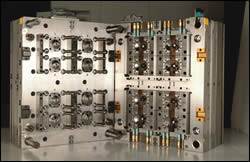

Automation and Moldmaking: Streamling Processes

Automation is coming into the forefront as moldmakers are on the hunt to automate with software and equipment to streamline processes for optimal productivity—and quality.

Read More

Challenges in Blow Mold Design

Blow mold design and build requirements—as well as challenges and how to overcome them—through the use of a new rotary blow molding wheel system.

Read More

Multi-Parting Line and Multi-Material Systems

Stack molds, co-injection, two-shot molding and their opportunities.

Read MoreThe Branding Myth

To not be aware and involved in marketing and branding is just as harmful as doing it poorly.

Read More

Cold Runner Manifold with Center Gate Provides Easy Operation, Maintenance

A cold runner manifold system for thermoset injection molds has been developed to overcome the challenges that come with using cold runners.

Read More

Laser Engraving/Marking: A Complement to EDM’ing and Milling

Laser technology may have a place in your mold build process when it comes to engraving and marking.

Read More

.jpg;maxWidth=300;quality=90)