March 2009 Issue

March 2009

Features

Featured articles from the March 2009 issue of MoldMaking Technology

Are We Being Commoditized?

Look around. Whether you’re a supplier that thinks you’re special or a buyer that thinks you have a product that no one can afford not to bid on, you’re fooling yourself. There are many reasons for this.

Read More

Considerations for a High-Feed Milling Strategy

High-feed milling is becoming the chosen methodology for removing as much material as possible in the shortest amount of time, as more shops equip themselves with high-speed CNC machining capability and sophisticated CAM programs.

Read More

Top 10 Machine Vision Improvement Opportunities

As the global manufacturing market continues to get more competitive, it is important to ensure that automation processes are running at peak efficiency levels. Any process-related malfunction is considered downtime, and directly impacts company profitability. Machine vision is an area that, when set up correctly, can reduce process inefficiencies.

Read MoreTwo for One

The MoldMaking Expo will be taking place alongside NPE, the triennial, international plastics show (www.npe.org).

Read More

Designing for Downstream

Steps can be taken to deliver to your customer not only a better performing tool, but a better performing tooling investment.

Read More

Momentum Forecast to Build in Second Half of 2009

42.1 Total Mold Business Index for January 2009 The total Mold Business Index is a weighted average of the sub-indices for new orders, production, employees, backlog, exports and supplier deliveries.

Read More

Reducing Fixturing Costs with Magnets

A look at magnetic workholding solutions, applications and benefits.

Read More

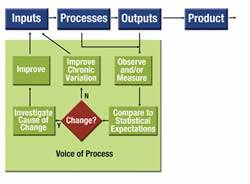

Statistical Process Control: Beyond the Data

Statistical process control used correctly allows moldmakers to connect data sources, collect data and issue failure alarms in real-time.

Read More

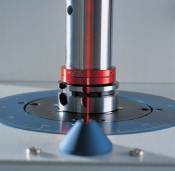

Increase Productivity with Balanced Toolholder Assemblies

During these times of economic uncertainty, it’s more important than ever for manufacturers to make sure they are getting the most efficient and productive use of their equipment. Operators of machine tools can do this by finely balancing the tools and toolholders being installed on their machines.

Read More

Going Green Can Garner New Business

Adopting green initiatives is not only important to your business, it is important to your customer and should be a part of your standard business practices.

Read More

The Common Ground Between Moldmaking and Aerospace

Many of the proven technologies used for mold and die machining can also be used in difficult to machine aerospace materials.

Read MoreThink Global, Act Local!

Scan the headlines today and the news ranges from simply insane to the absurd.

Read More

Business Opportunities in Aircraft Rise Above Economic Turmoil

Moldmakers who adapt to changing markets will find demand for their skills in aerospace.

Read MoreThe American Manufacturing Trade Action Coalition

This grassroots effort pledges to raise awareness on this country’s current trade policy and effect change to level the playing field in regards to U.S. manufacturing.

Read More

How to Decrease Your Internal Mold Maintenance Costs, Part 1

With an ultrasonic cleaning system, a mold shop can realize savings in cost, time and labor, as long as they are educated on the technology, the cleaning solutions and what works best for their particular situation/environment.

Read More

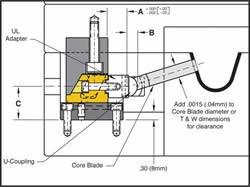

Improving Quality and Lowering Mold Component Cost

Ejector and core pins come off the grinding machine with an SPI 4-5 surface finish when using special grinding process technology and proprietary diamond grinding wheels.

Read More