January 2013 Issue

January 2013

Features

Featured articles from the January 2013 issue of MoldMaking Technology

Simple Considerations for Automated Mold Machining

A streamlined approach to your mold manufacturing process is accomplished most effectively through machine automation.

Read More

Using Simulation to Locate and Size Gates

Considerations and trade-offs when determining proper gate locations with simulation, which helps all stakeholders make a sound decision based on the priorities of the project.

Read More

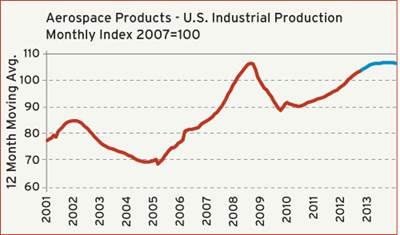

Aerospace & Automotive

Aerospace Outlook: Steady Growth in 2013; Automotive Industry Will Remain a Bright Spot in 2013

Read More

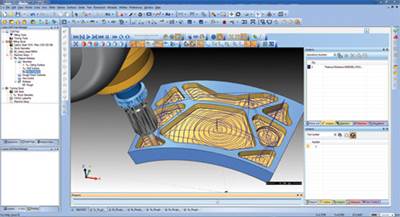

The Benefits of Modular CAD/CAM

Modular CAD/CAM software allows different software functionalities to be available independently of one another.

Read More

Help Your Customers Reduce the Cost of Making Plastic Parts

How to take advantage of the properties of DLC coatings to design better molds and improve cycle times.

Read More

CAD/CAM’s Role in Customer Collaboration

Seven skills—enhanced by the right CAD/CAM solution—that will help you win more business.

Read More

What Moldmakers Should Know about Cylindrical Grinding

Reducing costs, producing superior surface finishes and providing high flexibility are just a few of the advantages achieved with cylindrical grinding in mold manufacturing.

Read More

Molder’s Increased Tooling Capabilities Accelerate Time-to-Market

Spectrum Plastics Group—headquartered in Minneapolis, MN, but with additional facilities in Colorado, Connecticut and New York—provides custom manufacturing solutions for its customers in the medical, aerospace, defense and precision industrial industries. An alliance with an unnamed tool and design manufacturing company in the Twin Cities area is the next step for the company to meet its customers’ needs for high quality, quick-turn tooling.

Read More

Healthcare Reform in 2013 and Beyond

The recent ruling on the Patient Protection and Affordable Care Act (PPACA) by the U.S. Supreme Court has given employers much to consider for the future of their sponsored healthcare plans.

Read More

Rapid Mold Solutions, Inc.: Three-Pronged Approach to Prototype/Production Mold Manufacture

According to Rapid Mold Solutions President Damian Kuzmin, the company’s business plan was a simple one at the onset. “We wanted to service the prototyping needs of the Big 3 and the Tier 1s that supplied their specialty component needs,” he states, “we learned how to design, build, and produce parts at the price point and timing necessary to earn a lot of business quickly”. The difficult part, as it turned out, was determining what to name the new venture. ‘Radiator Mold Shop’ just wasn’t conducive to future expansion into new markets, so from the acronym RMS, Rapid Mold Solutions was born.”

Read More

_300x250 3.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)