February 2013 Issue

February 2013

Features

Featured articles from the February 2013 issue of MoldMaking Technology

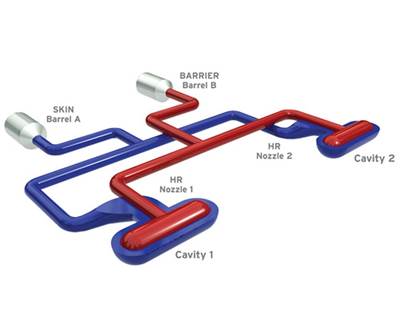

It’s Time to Reevaluate Co-Injection Technology

With the development of new resins, hot runners and controls technology, co-injection is positioned to move from a niche market application to mainstream acceptance in the upcoming years.

Read More

A “Run for the Border” Expands Transportation Market Niche

“This opportunity demonstrates how a great relationship can develop into a partnership with customers, as we’ve become very much a value-added supplier to them. We’re co-located with them and that strategy lends itself to other OEMs looking for similar relationships.”

Read More

Improve Input Quality with the Right Tool Inspection and Monitoring System

Integrating efficient tool inspection before and after the cut with optimized tool performance in the cut improves mold manufacture’s efficiency and profitability.

Read More

Inspection/Measurement Advances Yield Better Molds Faster

A roundtable discussion of the latest trends and developments in mold inspection and measurement technology highlights the cycle time reduction, accuracy improvement and cost decrease benefits.

Read More

Tips for Successful Hard Milling of Complex Molds

And when mold and die applications demand hard milling of materials up to 66 HRC, using the right end mills, cutting parameters and machining methods is critical for success.

Read More

Taking Advantage of Carbide Material for Your Mold Designs

The development of an end mill that can cut 3D features into a carbide material demonstrates how mold manufacturers can reap the benefits of carbide material for their mold designs without a time or cost penalty.

Read More

Reshoring Efforts Conquer Time-to-Market Crunch

Challenges in time compression, complexity, communication and cost force project back to the States.

Read More

Advanced Manufacturing Consortium: Addressing the Skilled Labor Shortage

“Programs like these are working on rebranding manufacturing into a more computerized and clean environment views—and most important—jobs that will lead to other careers, such as designing, supervision, quality and/or leadership.”

Read More

.jpg;maxWidth=300;quality=90)