June 2015 Issue

June 2015

Features

Featured articles from the June 2015 issue of MoldMaking Technology

Designing a Better Heat Exchanger - Part 2

In part two of our three-part sub-series on mold water cooling systems, we review water quality and its impact on mold performance.

Read More

2015 Leadtime Leader Awards Winner: Cavalier Tool & Manufacturing - Setting the Pace Holistically

This mold manufacturer has radically transformed its business by instituting a standardized, flexible process, advanced technology and a people-centric philosophy.

Read More

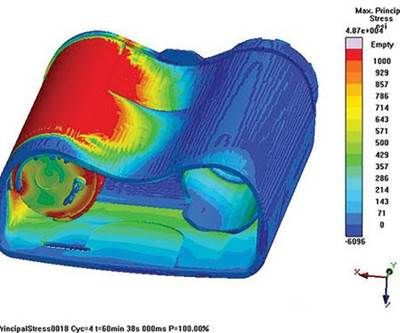

Minimizing Costly Tooling Issues

Properly reviewing a mold design before manufacture can help avoid new tooling issues.

Read More

Eliminating Seams

A zero-parting-line process requires collaboration among the toolmaker, its texturization provider and the OEM.

Read More

Ease Shop Management

One of the biggest challenges of properly implementing enterprise resource planning (ERP) software is making sure it includes all necessary information, but even a basic ERP solution can positively impact a mold shop.

Read More

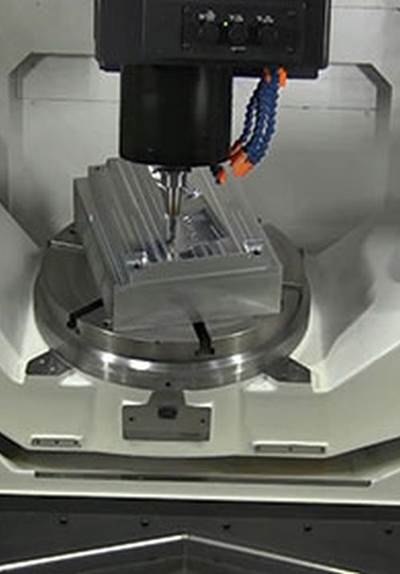

Increasing Five-Axis Accuracy

Probing and five-axis auto-tuning can correct machine misalignments in minutes, not hours.

Read More

Machining Deep with Solid Carbide Drills

A new twist on deep-hole drilling strategies for mold machining.

Read More

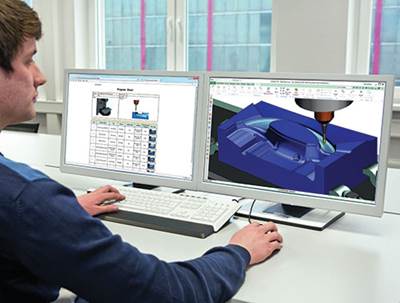

Beyond Integration

CAD/CAM integration has reached an entirely new level of value within process planning.

Read More

2015 Leadtime Leader Awards Honorable Mention: Dynamic Tool & Design - Committing to a Scientific Process

This shop’s recent strides in mold qualification mirror an ongoing transition to a more systematic approach to mold manufacturing. Meanwhile, a culture of ownership ensures a full buy-in from veteran employees as well as fresh talent attracted through extensive workforce development efforts.

Read More

Multi-Material 3D Printers Feature Triple-Jetting Technology

Stratasys offers six multi-material 3D printers with compact and mid-size build envelopes that all feature the company’s PolyJet triple-jetting technology.

Read More

Diamonds in the Roughing

This mold manufacturer discovered significant time and cost savings in a previously unexplored feature of its CAM software.

Read More