October 2014 Issue

October 2014

Features

Featured articles from the October 2014 issue of MoldMaking Technology

Tackling Wear with Vacuum Heat Treating

This heat-treatment process provides critical temperature and wear-resistance properties to certain mold steels.

Read More

Tool Up with Rapid Heat/Cool Technology

A rapid heating and cooling technique using pressurized water solves sink, weld line and discoloration problems.

Read More

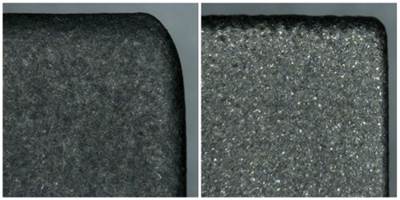

Graphite vs. Copper Electrode Material for EDM Applications, Part 2

Test findings and a cost of ownership model help identify the monetary impact graphite and copper electrode materials have on manufacturing.

Read MoreIn the Trenches: Think Like a Toolmaker

Fundamental knowledge and understanding is necessary in mold repair.

Read More

Optimizing Common Roughing Technology

Keeping on top of the ever-advancing range of cutting technologies, edge geometry designs, materials and coatings is essential for achieving higher productivity, faster metal removal rates and more cost-effective machining processes.

Read More

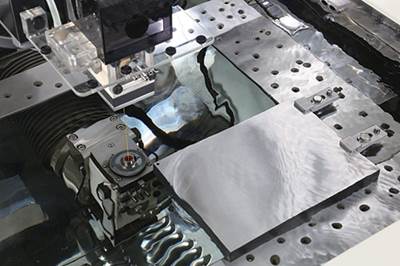

Truly Smart EDM

Think ease of use, ergonomics and expertise when empowering your operators with the right EDM.

Read More

.jpg;maxWidth=300;quality=90)

_300x250 4.png;maxWidth=300;quality=90)