August 2009 Issue

August 2009

Features

Featured articles from the August 2009 issue of MoldMaking Technology

Honoring the Industry

The Annual Leadtime Leader Awards—sponsored by Progressive Components—were designed to recognize outstanding North American mold manufacturers.

Read MoreThe Value of Lean

Last month, I wrote of the value of manufacturing and business communities taking active roles in supporting the shops and plants that make up their local eco-systems. I gave examples of how some communities and groups have been very successful at helping their communities thrive through those efforts. Ironically, I recently heard some interesting news about our largest community—our country—that got me to thinking of how important it is for us to help ourselves as individual companies.

Read MoreBe Proactive, Not Reactive

News from the auto industry today is full of doom and gloom. However, there are steps mold manufacturers can take to remain profitable during this time.

Read MoreFive Tips for Capital Equipment Purchases

Cash flow is the foundation of any business, but it plays an especially important role when it comes to capital equipment purchases. By financing such purchases, businesses can realize several benefits, such as more consistent cash flow, preservation of working capital, better management of the company’s bottom line, tax advantages, streamlining of the purchasing process, and preservation of bank lines of credit.

Read MoreIt’s Time to Advertise

We are into another one of these cycles that the mold building industry goes through.

Read More

The Right PC CNC Brings Speed to Moldmakers

What to look for in a control to get the speed, accuracy, surface finish, flexibility, convenience and value a moldmaker needs.

Read More

Detecting Water Flow Restrictions

A look at how taking the time and data to analyze a mold problem will help you repair it right—and permanently—the first time.

Read More

Reduce the Time and Costs of Jig and Fixture Manufacture

When it comes to the manufacture of jigs, fixtures and assembly tools, time-to-market for new products can be reduced, overall costs can be saved and the quality of the resulting components/production can increase with the use of additive fabrication—laser sintering and fused deposition modeling.

Read More

Reaching Out to a Different Market to Survive Tough Times

This mold manufacturer has reassessed its market base and began dabbling in the energy industry based on its experience with CNC machining—making it a natural transition.

Read More

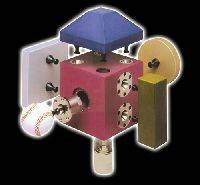

Quick-Change Devices Reduce Setup Time

A line of quick-change devices has been developed that serves as a replacement for traditional nuts and bolts and can reduce setup time.

Read More