January 2007 Issue

January 2007

Features

Featured articles from the January 2007 issue of MoldMaking Technology

Organizing Your Shop Through Communication

Visual communication is a key factor when choosing an organizational tool.

Read More

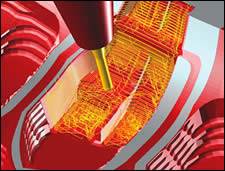

How to Achieve Economical Five-Axis Milling

Although moldmaking has not had great incentives to invest in five-axis technology like the aerospace industry, there are still many reasons for moldmakers to adopt five-axis machining, and there are a few interesting software functions that help to make five-axis programming economical.

Read MoreLearning Outside the Shop

What better way to learn outside the shop than to attend some trade shows.

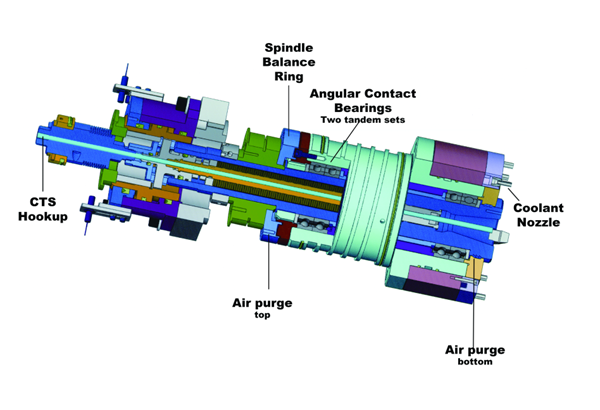

Read MoreJig Grinding, EDM or High-Speed Milling?

When evaluating new processes for mold manufacture, jig grinding is worth a second look as machine manufacturers have now added high accuracy features to guarantee repeatable results.

Read More

Part Two of a Two-Part Series Optimizing Mold Performance And Maintenance Efficiency

The last three steps of a six-step process for strategizing for improvement in shop operations when it comes to how we maintain molds.

Read More

Precision Manufacturing Institute: Specialized Training

This school works hand-in-hand with suppliers and shops—relying on their expertise and input to stay on top of industry trends and help develop a tailor-made curriculum in precision machining and moldmaking.

Read More

Guidelines to Put Your Production Process on the Profitability Track

A top-down commitment to investigate new options for molding materials, release agents, training techniques and equipment is critical to reduce mold downtime.

Read More

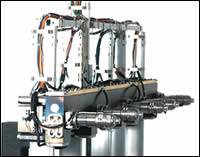

Advances in Hot Runner Systems Drive Innovations in Part Engineering and Styling

Design and performance capabilities of components fabricated in state-of-the-art molds enhance the appeal of new vehicles.

Read More

Chicago Mold Engineering: In The Spotlight

Focusing on a niche in the automotive headlap reflector market—coupled with the most advanced technologies and mold manufacturing techniques—lights the way for this moldmaker’s 2007 Leadtime Leader Award: Large Shop.

Read More

The Moldmaker’s Role in Controlling the Molding Process

How the toolmaker/mold designer can make the best choices when it comes to in-mold cavity sensing and control; how to do a good installation; basic functionality of the sensors; and, post installation care.

Read More

.jpg;maxWidth=300;quality=90)