amerimold 2013: Establishing and Educating a Mold Buyer/Mold Builder Team

The conference portion of the Expo—both our new show floor Knowledge Center presentations and our three-track technical conference program—received attendance levels not experienced in a few years.

Share

Read Next

Several attendees attributed their attendance this year to business levels being at the point where it is necessary to get themselves and their employees out of the shops and into a learning environment to see and hear about the latest and most effective technology and business strategies in action.

The technical conference kicked off with a packed room of mold shop senior managers, mold purchasers, mold designers, part designers and processing engineers eager to learn about various techniques and methods for improving mold design.

This morning ENGINEER block of sessions was sponsored by the Mold Making and Mold Design Division of the Society of Plastics Engineers and moderated by Glenn Starkey of Progressive Components, who lead the presenters through three panel discussions--facilitating interactive Q&A and raffling off some membership prizes.

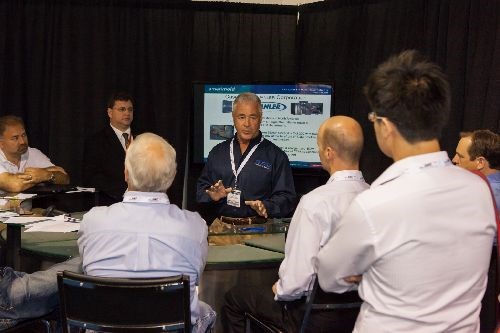

The afternoon continued with the debut of our new exhibitor Knowledge Centers-intimate, expert-led technology and application-specific presentations on products and processes for better moldmaking and molding featured on the show floor.

Following a few of the Knowledge Centers, several attendees visited the participating exhibitors for deeper discussion. They were also able to seek out our new and returning Moldmaker exhibitors--including JMMS, Mold Tech, Janler, VistaTek, Tech Mold, Micro Mold, to name a few--to learn about their specific experiences with the variety of technologies spotlighted in the Knowledge Centers--e.g, CAD data workflow, product design principle, advanced valve gate control, tackling shrink and warp, EDM, 3D rough milling, HSM, modular inspection, in-machine mold leaning, mold protection and laser welding.

The BUILD conference block sponsored by TMA coincided with the Knowledge Center kickoff, but held its own as attendees were able to take advantage of both educational opportunities.

One attendee expressed how being able to bounce back and forth from the technical conference panels to the Knowledge Centers allowed him and his team to learn theory on a few processes and strategies and then get a look at the specific technology on the show floor through the exhibitor presentations--such as process optimization and program management of new and transfer tooling from Thogus in the Technical Conference, and then visit Beaumont's Knowledge Center and booth to learn about its related plastics training.

The MAINTAIN Block sponsored by ToolingDocs helped to develop awareness and planning for more proactive mold maintenance by molders and their mold builders through three panels covering cleaning, welding, troubleshooting and training.

Several toolroom managers at molding facilities as well as molding facility owners and plant managers were thrilled to walk away from this block, not only with action times, but solid contacts on whom they could rely for any necessary follow-up assistance.

All in all the educational aspects of amerimold 2013 not only helped moldmakers get into the game, but also bridged the gap between the mold buyer and mold builder establishing a team ready to take the industry to the next level ... and planning for amerimold 2014 has already begun!

_300x250 4.png;maxWidth=300;quality=90)