Achieving High Value Customer Relationships

Mack Molding details how it cultivates relationships with its mold manufacturers and how these collaborations better serve its OEM customers.

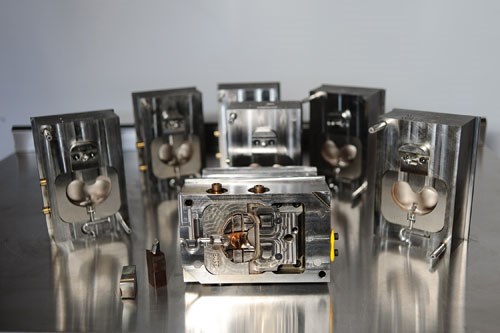

Mack Molding (Arlington, VT)—a leading supplier of plastic injection molding and contract manufacturing services with core competencies that include part design, prototyping, engineering, finishing operations, full-service machining, assembly and supply management—places high value on the company’s relationships with its tooling providers.

The company operates out of both northern and southern divisions and serves a number of industries, including medical, industrial, transportation, computer and business equipment, consumer markets and energy/environment.

According to Mack Molding Director of Procurement Marc Colety, Mack Molding primarily selects its own vendors rather than looking to its OEM customers for direction. “For the most part, we hire our own tooling vendors based on the specific requirements of the job,” he states. “While we are certainly flexible to our customers’ preferences, they rarely insist on where the tooling is placed. Some OEMs have very knowledgeable tooling engineers who prefer specific overseas or domestic sources, but the majority depends totally on us to recommend tooling sources and direction.”

Mack’s OEM customers may not specify a toolmaker, but they do clearly outline their needs and expectations, which directs Mack to a source grouping, according to Colety. “An example of this is cost,” he notes. “If cost is the most important factor, we would choose one direction. If time is most important, that might direct us in another. Our capabilities are so diverse that we must have an extremely large and diverse supply base with specialties like quick-turn, tight tolerance, highly cosmetic, high cavitation, large parts, small parts, shops that can handle a large program (maybe 60 to 100 tools)—as well as experience with processing methods, like internal or external gas assist. These are all specialties we have within our tool supplier portfolio.”

Tooling Vendor Selection

Over Mack Molding’s 92-year history, the company has developed a “robust” Approved Vendor List (AVL)—a subsection of which is moldmakers. “The list is dynamic and constantly changing to include only those suppliers remaining relevant with the evolution of new technology,” Colety elaborates.

To get on Mack’s AVL, a moldmaker first has to complete an extensive Tooling Vendor Survey, which solicits information on facilities, machinery, quality processes, how tools are built, etc. In addition, Mack might also conduct an on-site audit, as well as a financial risk assessment. “If the moldmaker completes these steps satisfactorily, it will be added to the AVL,” Colety says. “Mack’s AVL includes shops that excel in small molds, large molds, aluminum molds and hardened steel molds. When we send out an RFQ for a mold, we consider each moldmaker’s area of expertise, so only the appropriate shops invest time in developing the quote. We also make every effort to maintain good working relationships and open communications with our tooling sources so we are aware of their workloads when requesting quotes. A shop’s current workload can be a factor in its tooling prices.”

Colety emphasizes that the most important criteria for Mack Molding are quality, price and on-time delivery. “Since any toolmaker quoting for us is on our AVL, we already know they will provide quality,” he states. “In general, our expectations are tied to our mold specifications. Mack develops very detailed specification packages, which identify tool construction, safety requirements, standardized components and fittings, etc. So when a tool shop quotes a project, they must meet our specs. In some instances, we also require Certificates of Compliance for the type of steel used, as well as a Rockwell hardness reading. In terms of our involvement, we work hand-in-hand with the toolmaker throughout the complete design and build process.”

One of Mack’s biggest challenges is determining the very best method to build a mold. “Almost every mold can be built in more than one way,” says Application Development Center Director John Zuk. “Mack is responsible for determining the best method, material and design that will ultimately produce the optimum solution. Molds today are becoming more complex, since one of the major thrusts for injection molding is part consolidation. An assembly that once had 20 unique parts and molds may now be consolidated into five parts and molds. The result is a more complicated tool that may have actions, lifters, slides, double actions, etc. So creativity in complex mold design is critical. After we provide a detailed and documented expectation for the tool, we expect the toolmaker to follow-up with a 3-D model. From that dialogue, we arrive at a final tool design.”

Another challenge the company faces is using U.S. suppliers versus offshore suppliers. “Fortunately, some of our suppliers have invested in new equipment so they can machine faster,” Colet says. “They also are using their shops more wisely, 24/7. A few of our domestic strategic partners have also established partnerships with Asian sources. This allows us to communicate in English, deal domestically, benefit from the Asian savings, and offer customers another less risky option. Our domestic sources get the business by having the high labor portion of construction done offshore, while handling engineering, final assembly and texturing in the U.S.”

Mold manufacturers that wish to work with Mack Molding should be established tooling vendors that can demonstrate financial solvency, Colety states. They must be able to demonstrate the fiscal responsibility necessary to manage large programs,” he notes. “They must be on top of current technology and capable of producing a wide range of tools. It is also helpful if a toolmaker has both domestic and offshore sourcing. Vendors who can lower tool costs, improve time-to-sampling, and build low-maintenance molds that run faster cycles definitely have an edge.”

“Another capability is design and engineering services,” Zuk adds. “We have more and more customers coming to us to finish the part design and perform mold fill studies. A supplier who could also offer these services would add significant value.”

“The bottom line for contract manufacturers today is cost reduction,” Colety continues. “Our customers send RFQs to multiple molders. The pressure to return quotes quickly and at the most competitive cost is huge.”

That said, slashing profit margins is not the only way to achieve cost competitiveness, Colety concludes. “This is where creativity comes into play. For example, our prototyping division, Mack Prototype, recently worked with tool designers to develop a concept that would produce 24 different part numbers using only four modular dies, five additional cavities and two core sub-inserts. This greatly decreased the number of molds required for the entire launch, resulting in substantial savings in both cost and leadtimes.”

So, at the risk of sounding cliché, sharpen your pencils and think outside the box. Creative, cost-effective tooling solutions will determine your future.

---------------------------------------------------------------------------------------------------

About Mack

Mack Molding has two divisions —Northern Operations and Southern Operations. The company’s Northern Operations include four injection molding facilities in Vermont and Massachusetts. The Northern Operations has 85 presses ranging in size from 28-2000 tons of clamp force, as well as 11 gas-assist units. The Northern Operations also serve as home to MackMedical, the company’s medical products group.

Mack Molding's Southern Operations includes two injection molding facilities in Inman, SC and Statesville, NC. Primarily focused on large-part molding, the Southern Operations has 40 presses in total, with 20 ranging in size from 1000-4000 tons of clamp force, as well as 13 gas-assist units. Click on individual locations below for more details.

Mack also manufactures custom molded plastic components and assemblies for all of the major heavy truck OEMs, and is certified to the ISO/TS 16949 international standards for the automotive industry. The Southern Operations' environmental management system is also certified to ISO 14001.

Tooling Vendor Checklist

A short list of tooling vendor expectations from Mack Molding:

• Quick turnaround and accuracy when quoting

• Open communication

• Willingness to stand behind and take responsibility for your work

• Ability to meet strict product requirements

• Creative mold design for difficult features

• Thorough understanding of plastic part design, engineering resins and processes (including gas-assist, internal and external)

• Appreciation and respect for Mack’s high standards (no cutting corners)

• Creative cost-reduction ideas without impacting quality

• Robust tool building systems

• Clean, up-to-date facilities

For More Information:

Mack Molding / (802) 375-0334

marc.colety@mack.com / mack.com

Related Content

The Trifecta of Competitive Toolmaking

Process, technology and people form the foundations of the business philosophy in place at Eifel Mold & Engineering.

Read MoreEditorial Guidelines: Editorial Advisory Board

The Editorial Advisory Board of MoldMaking Technology is made up of authorities with expertise within their respective business, industry, technology and profession. Their role is to advise on timely issues, trends, advances in the field, offer editorial thought and direction, review and comment on specific articles and generally act as a sounding board and a conscience for the publication.

Read MoreMMT Chats: Marketing’s Impact on Mold Manufacturing

Kelly Kasner, Director of Sales and Marketing for Michiana Global Mold (MGM) talks about the benefits her marketing and advertising, MGM’s China partnership and the next-generation skills gap. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreMold Builder Uses Counter-Intuitive Approach for Mold Challenges

Matrix Tool Inc. answers customers’ hard questions with creative solutions for cavity spacing, tool sizing, runner layout and melt delivery that reveal the benefits of running in a smaller press size at lower cavitation but higher yield.

Read MoreRead Next

K’NEX/Rodon Team Makes Strong Case for U.S. Manufacturing

Rodon takes a solid relationship with toy giant K’NEX and applies its business model to other manufacturers—taking domestic manufacturing to the next level.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

.jpg;maxWidth=300;quality=90)

_300x250 4.png;maxWidth=300;quality=90)