A Perfect Tool for Modeling a Mold with Multiple Curves and Flowing Shapes

Design-intent modeling greatly reduces the time required to transform a bottle or mold into an editable CAD model for further design and manufacturing.

Share

When consumer meets bottle, it’s either love at first sight or immediate rejection according to Krones AG, an international leader in designing and manufacturing beverage packaging. Whether the consumer knows it or not, Krones maintains that “design is the most effective means to attract people emotionally and to give a brand its distinctive character.”

With so much riding on the design of a bottle, it would make sense that brands would want to hang on to the shapes that register an emotional pull on the buyer. But until recently, recreating a classic design was more easily said than done.

As is the case with many other consumer products, some existing bottle and mold designs that give a brand character don’t have CAD data associated with them. In the past, that would mean painstakingly recreating the design with measurements, sketches and CAD modeling from scratch. Today, it’s a fast and accurate reverse engineering process using 3-D scanning and Geomagic software.

Aesthetics Meets Efficiency

When recreating familiar or iconic designs, accuracy is everything. According to Krones, Geomagic software helps the company ensure that design aesthetics are recaptured and that the technical specifications are optimized for manufacturing lines used to produce the finished bottles.

Reverse engineering with Geomagic Studio enables Krones to take full advantage of processes such as stretch blow molding, which produces a plastic container from a preform or parison that is stretched into a desired shape.

Recreating the Physical World

The process at Krones begins with a Steinbichler Comet 5 white-light scanner. A white-light scanner projects fringe patterns onto the object’s surface, which are then recorded by two cameras. The captured data in Krones’ case is represented as triangulated meshes (STL data) with edge lengths between 0.005 mm and 4 mm. A typical mold scan can contain as many as two million triangles.

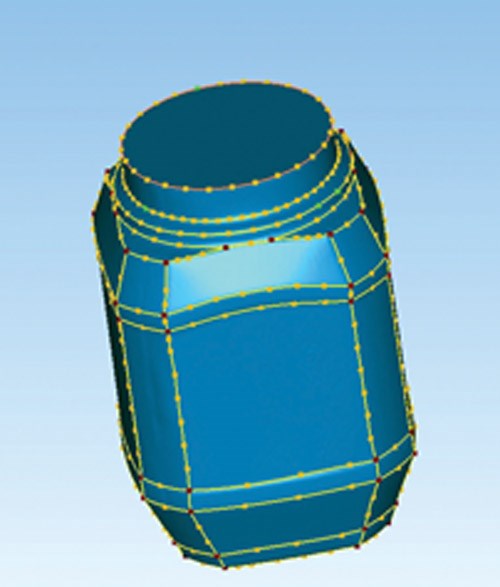

Within Geomagic Studio, the scan data goes through what Krones calls conditioning. This involves filling any holes that might have been left by the scanning process and smoothing, fitting, trimming, projecting and extending boundary edges as necessary. The result is an accurate, water-tight digital polygon model, which is then aligned and scaled to the proper size.

Two Modelers Meet Different Needs

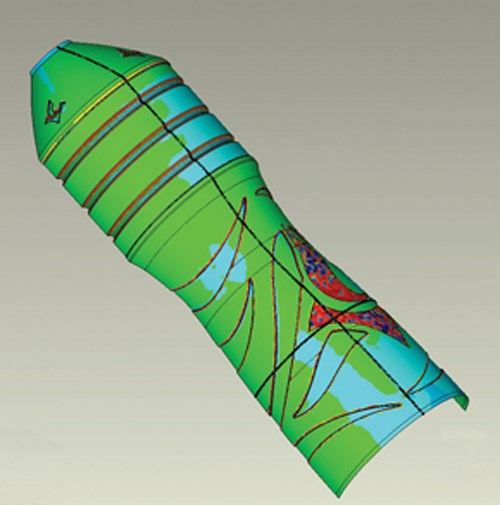

Depending on specific design needs, Krones takes advantage of the two modelers available within Geomagic Studio: one for organic shape modeling and one for design-intent modeling.

Organic shape modeling in Geomagic Studio creates water-tight NURBS surfaces when Krones wants to create exact 3-D replicas of existing bottles or molds. It is the perfect tool for modeling an organic object such as a bottle or mold with multiple curves and flowing shapes.

Design-intent modeling (formerly called Geomagic Fashion) within Geomagic Studio enables objects to be modeled as they were originally designed—with a combination of primitive shapes, swept features and freeform surfaces.

Using design-intent modeling, Krones captures both dimensions and features such as radii, spot-bars, base contours, labeling areas, emblems and transitions from scan data. This ensures the precise dimensioning required for tasks such as applying labels onto bottles. Design-intent modeling greatly reduces the time required to transform a bottle or mold into an editable CAD model for further design and manufacturing.

Completed models from Geomagic Studio are saved as standardized .igs or .stp files or proprietary Geomagic .wrp files. The format depends on the department the files are going to within Krones and the CAD program being used. There’s also the option of using Geomagic’s Parametric Exchange program to create optimized, parametric CAD models that are editable within popular CAD software.

Return of an Old Friend

The 3-D models created in Geomagic Studio are the basis for further design processes at Krones using either Solid Edge or Siemens NX CAD systems. To ensure quality, Geomagic Qualify 3-D inspection software is used to capture bottles during production runs and compare them to the CAD model for deviations and to clarify Krones’ technical specifications.

The recreation of a successful bottle has implications throughout the product chain. For designers and engineers at Krones, 3-D scanning and processing using Geomagic software means fast, flexible workflows that save time and enhance quality. Krones customers are happy to see the reincarnation of a proven brand. Consumers, of course, are unaware of the technological innovation that took place behind the scenes—they are just glad to see a familiar, friendly shape on the store shelf.

Related Content

Advances in P20 Steel Potentially Eliminates Need for Stress Relieving After Rough Cutting

Omega Tool Corp. compares conventional, new P20 grades side by side in production fascia tools, finds no downside.

Read MoreConsiderations for Mold Base Material Selection

Choosing the right material can greatly affect the profitability and cost of your application.

Read MoreOEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

Read MoreWomen Impacting Moldmaking

Honoring female makers, innovators and leaders who are influencing our industry's future.

Read MoreRead Next

3-D Laser Scanning Opens the Door to Inspection And Reverse Engineering for Moldmakers

Next-generation scanning technology precisely captures large and small molds.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

_300x250 4.png;maxWidth=300;quality=90)