A Different View of Faster Moldmaking

Timesaving software shortcuts and a choice of materials give a rapid prototyping shop a competitive edge.

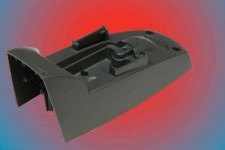

Speed is everything for Dynamic Plastics, Inc. Its market niche demands it. The company specializes in rapid manufacturing of prototype plastic injection molds for customers who need small, but high-quality parts-also provided by Dynamic Plastics (see Photo 1).

Dynamic Plastics' combination of skilled designer/programmer/machinists, materials selection and scheduling flexibility on the shop floor, is key to its success. User-friendly CAD/CAM/CNC software and a work coordinate system creating new, local orientation of designated part structures, has given the company a competitive edge in many time-critical prototyping scenarios. First-time-accurate machining in high-quality aluminum sets them up for production right from the prototype stage.

Growing a Flexible Shop

Owners Joe Doss and Jim Connell tell a story typical of many niche moldmakers: they started in a garage, invested in quality CAD/CAM/CNC software, took increasingly complex rush-delivery jobs, and hired, trained and expanded the workforce. That was ten years ago.

Now in a twenty-five thousand square foot facility in Chesterfield Township, MI, Dynamic Plastics employs twelve moldmakers and thirteen support/management staff. "We're always being pushed to get things 'today' at production quality," says tooling manager Tom Prebelich.

"What sets us apart from a lot of our competition is our triple-duty moldmakers. For most jobs, they not only write toolpaths and do the machining; they do their own design work. Our choice of what we feel is the CAD/CAM/CNC program with the most user-friendly interface allows our crew the latitude to apply a wide variety of their skills to get the whole process done quickly and accurately."

Cutting Time

"They can take virtually any kind of file into Mastercamr," Prebelich observes, "and move the job right along. In a real rush situation, they'll separate the customer's model, design the cavity mold, and hand that off to another operator so machining begins on the job even before the whole mold is designed.

"The production time constraints and our own quality control don't leave room for dealing with flash, either. The mold parts must fit right the first time out. Using MoldPlusr (an add-in for Mastercam) we copy the run-off and parting line surfaces for the cavity mold into the core mold layer for that perfect fit. In the five years we have used MoldPlus, it has given us a time savings of up to 70 percent on the most complex jobs."

According to Prebelich, "We're now in the process of fine-tuning production even further using the solids functions of Mastercam/CNC Software (Tolland, CT). Our moldmakers can't believe it's so easy to use. The time saved by solids offsets the learning curve with no slowdown on the floor, so they're getting up to speed by using solids on real projects."

Measuring Success

Badger Meter, Inc., is one end user of Dynamic Plastics' fast-forward, quality production. Badger is a leading worldwide product marketer and manufacturer using flow measurement and control technology. Its ReadAllr Interrogator, a microcomputer-based, battery-operated data collector, is the hand-held interface (see Photo 2) with Badger's Tracer automated meter reading system. It performs radio frequency automated meter reading data collections, manual data entry and programming of remote transponders. Dynamic Plastics won the bid for prototype molding and Dynamic Plastics' president, Joe Doss, met with the engineers.

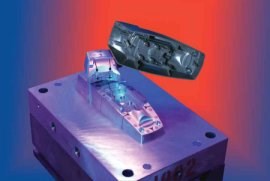

Based on his experience, Doss suggested changes in rib positions and gate locations for better molding, as well as some ideas to improve appearance and avoid sink marks. The team agreed on many of the changes and Dynamic Plastics was given a five-to-six-week turnaround time-for fourteen different parts (see Photo 3).

Drawing on Experience

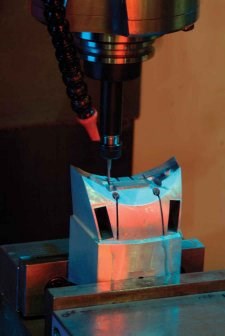

The ReadAll was designed to slide into (see Photo 4) a combination base/charging unit, one of the fourteen parts. Analyzing the solid model brought into Mastercam, Prebelich zeroed in on one section of the main base housing (see Photo 5) that needed special consideration. The alignment of bosses, windows and holes in the back section of the base-the part that positions the charging contacts-was nearly perpendicular to the main section's line of draw.

As with many of Dynamic Plastics' projects, this mold required a hand-load section, (see Photo 6) pulled in its appropriate direction from the cast piece after molding. A complex combination of five-sided contouring, pocketing and drilling, the hand load also had piggyback parts.

Explains Prebelich, "We designed the hand load from the solid model itself (see Photo 7), but I needed to change the construction plane (screen view) and tooling plane (relative to machine cutting) to orient it vertically to the rest of the mold."

By orienting all of the geometry to coordinates nonstandard to the original file, design and toolpathing the model section goes much faster. Prebelich used Mastercam's new work coordinate system (WCS) to simplify these issues. At its most basic, the WCS allows one to move the coordinate system to the part, rather than moving the part to the coordinate system. This makes it easier to define and work with parts whose origin and orientation need to be different from their original coordinate system.

"Our best option for a first-time prototype success was to use six different sets of coordinates and to write toolpaths for each orientation," Prebelich reports. "We're using three-axis machines (see Photo 8) because the investment in a five-axis mill wouldn't be cost-effective for our kind of production. So we just move the piece on the table, using a different tooling setup for each toolpath."

The WCS also has come into play when Dynamic Plastics programmers have opened a part and found that it's in a nonstandard orientation, then they determine that the part has to be programmed in its original orientation. The WCS also makes it easy to create and define work offsets and program parts that need to be flipped for machining. It's also useful in a number of other situations that keep Dynamic Plastics' reputation for rapid prototyping (RP) up to speed.

More Operations, Less Time?

Before isolating and re-coordinating the hand load from the major ReadAll mold, Prebelich entered the shrink rate of the custom plastic material into Mastercam. Information from the customer as to which surfaces were going to be show surfaces helped him determine which way to open and close the mold. In order to achieve the best result, he rotated the solid model so that the textured side was on the cavity walls (see Photo 9).

"I think we used about every toolpath Mastercam made available," Prebelich recalls. "Once the part was designed, I did all the drilling operations first-holes for ejection, ports and some other features of the part. Then I used a surface rough pocket toolpath to remove the majority of material with a 1/2-inch bullnose mill with a .030-inch corner radius.

"We like to do an intermediate semi-rough surface toolpath, stepping down to a 1/4-inch bullnose mill with a .020-inch radius to get it closer to the finish dimensions but still perform a fairly aggressive cut. Since our software remembers what it has cut, I was able to use the leftover feature with a much smaller cutter-a .060-inch flat or ball mill, depending on the geometry-to clean up stock from corners and details missed by the larger cutters. Finally, surface finish contour and, in some places, surface finish parallel toolpathing gave us an extremely clean mold surface finish."

Rather than adding machining time, Dynamic Plastics' three-step progression of toolpaths results in faster outcomes. Running appropriate feed-and-speed rates for each successive cutter in the progression keeps feed speeds high without pushing the tools to their respective limits. With this rough to semi-rough to finish combination, larger cutters give greater speed while leftover, with its quick cleanup, completes the details with time to spare.

Harder Aluminum = Quality + Economy

"If we cut the typical steel production mold," notes Prebelich, "the main mold body would be designed with a mechanism to pull the hand load during ejection. Because this is a prototype, time limits the complexity. Also, because it's a part with maybe 250 pieces molded a year, the extra time in hand pulling is offset by the unnecessary cost of a full-blown steel mold mechanism by thousands of dollars."

For Badger's ReadAll, Dynamic Plastics used Alcoa QC7 high-hard aluminum. "This metal withstands heat and abrasions from the plastic. Even though these are prototype tools," Prebelich continues, "we guarantee our tools for fifty thousand-part runs (see Photo 10).

The QC7 also makes for better machining. Many softer aluminums get gummy during cutting and stick to the cutters. Not only does the QC7 give us faster machining, it polishes well for lenses, among other fine-finish areas.

"Cost-wise, using the better quality stock is perfect for our high-quality, low-run customers. We can meet the quality standard of steel production tools and give our customers great turnaround at their low production requirements for as little as half the cost."

The configuration of Dynamic Plastics' production process-from its choice of materials, software and equipment to the decision to train the technicians as designers/programmers/machinists-contributes mightily to the company's niche.

And the customers are happy. They get RP at first-line production quality and production parts that suit their low run needs, all from a single, low-cost mold. Dynamic Plastics' QC department consistently confirms that its product meets customers' quality specifications. In a tight market, you can't get better than an ongoing win-win relationship with your niche customers.

Related Content

Mold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

Read MoreTolerancing in Mold Design, Part 1: Understanding the Issues of Conventional Bilateral Tolerancing

Mold designers must understand the location, orientation and form limitations of conventional tolerancing before changing to another dimensioning system.

Read MoreMoldMaking Technology's Most-Viewed Content 2022: Products

MMT shares the five top-viewed technologies, equipment and services of 2022 in each Engineer, Build, Maintain and Manage tenet based on Google Analytics.

Read MoreOEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

Read MoreRead Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

.jpg;maxWidth=300;quality=90)